Brochures & Whitepapers

Keep up-to-date with IS³

Speak to an Expert

Contact one of our highly qualified sales representatives to see how we can assist with maximising your potential!

Generic Drum Unit Simulator Boosts Productivity at South African Power Plant

Background

SOUTH AFRICA – Located between Vereeniging and Sasolburg, the Lethabo Power Station, owned by Eskom Holdings, is responsible for over half of the electricity generated on the African continent and provides affordable electrical power to an increasing percentage of the African population.

Eskom Holdings generates, transports and distributes approximately 95% of South Africa’s electricity – making up 60% of the total electricity consumed on the African continent. Eskom is the world’s eleventh-largest power utility in terms of generating capacity, ranks ninth in terms of sales, and boasts the world’s largest dry-cooling power station.

Goals

- Install simulation system to help boost safety, efficiency and profitability at the plant

Challenges

- Improve productivity and plant operations, while increasing operator plant understanding, safety and reducing operating costs

AVEVA Solution

- DYNSIM Dynamic Simulation

Results

- The simulation system has reduced operating costs, while plant understanding and personnel safety have improved

- Assists in providing continuous electricity to 95% of South Africa (around 60% of the total electricity consumed on the African continent)

Improving Safety and Plant Profitability

AVEVA supplied an Operator Training System (OTS) at Eskom’s Lethabo Power Plant in South Africa that is helping to boost safety, efficiency and profitability at the plant.

Operator Training System Solution

Eskom realized that improved productivity depends on improved plant operation, which depends on the quality of its operators. As a result, in March 2004, Eskom took delivery of AVEVA Generic Drum Unit Simulator.

The Generic Drum Unit OTS is based on a sidewall-fired unit boiler coupled with a train of high, intermediate and low-pressure steam turbines. The simulator components include physical, first principles based dynamic simulation models, the instructor station, DCStype controls, and training for up to four operators.

The flexibility of the solution allows the emulation of the DCS interface through a single application, including alarming and trending, execution of the process model, and support of the instructor’s interface. This integrated solution allows the displays to be visible at every operator station for maximum training flexibility. This interface also requires minimal training for an instructor, allowing the focus to be on process training rather than navigating the simulator system.

Dan Wilbers, Managing Consultant of Operator Training Systems and Services, AVEVA said, “The generic drum simulator purchased by Lethabo is the result of AVEVA’s extensive experience delivering training systems to power generators around the world. We are excited that it has been chosen as the platform to build a solid performance improvement strategy at this facility.”

AVEVA delivered the Simulator on time and to budget. We are completing our training program on the Simulator and have been amazed at how easy the system is to learn and work with.”

Abrie Venter, Eskom Training Manager

Benefits Realized

The training program has already produced a lot of benefits. Operating costs have been reduced, while plant understanding and personnel safety have improved. Lethabo operators are able to maintain plant equipment in the normal operating range and prepare for off-normal operations such as valve breakage and tube leaks.

Accelerate time to value with AVEVA Industrial Cloud Platform

Enable the connected digital landscape and break down boundaries with an open cloud platform optimised for unlocking industrial insights in real-time.

Advantages of industrial hybrid SaaS solutions:

- Accelerate time to value – Adopt strategic industrial hybrid SaaS that are easy to deploy, access, and manage securely across any global enterprise.

- Flexible digital twin deployment – Enrich existing systems through hybrid SaaS solutions to create an industrial digital twin that delivers fresh value opportunities.

Read the full article by Engineering News who unpacked this topic at IS³’s prestigious annual X-Change User Conference.

Accelerate time to value with AVEVA Industrial Cloud Platform

Enable the connected digital landscape and break down boundaries with an open cloud platform optimised for unlocking industrial insights in real-time.

Advantages of industrial hybrid SaaS solutions:

- Accelerate time to value – Adopt strategic industrial hybrid SaaS that are easy to deploy, access, and manage securely across any global enterprise.

- Flexible digital twin deployment – Enrich existing systems through hybrid SaaS solutions to create an industrial digital twin that delivers fresh value opportunities.

Read the full article by Engineering News who unpacked this topic at IS³’s prestigious annual X-Change User Conference.

Accelerate time to value with AVEVA Industrial Cloud Platform

Enable the connected digital landscape and break down boundaries with an open cloud platform optimised for unlocking industrial insights in real-time.

Advantages of industrial hybrid SaaS solutions:

- Accelerate time to value – Adopt strategic industrial hybrid SaaS that are easy to deploy, access, and manage securely across any global enterprise.

- Flexible digital twin deployment – Enrich existing systems through hybrid SaaS solutions to create an industrial digital twin that delivers fresh value opportunities.

Read the full article by Engineering News who unpacked this topic at IS³’s prestigious annual X-Change User Conference.

Accelerate time to value with AVEVA Industrial Cloud Platform

Enable the connected digital landscape and break down boundaries with an open cloud platform optimised for unlocking industrial insights in real-time.

Advantages of industrial hybrid SaaS solutions:

- Accelerate time to value – Adopt strategic industrial hybrid SaaS that are easy to deploy, access, and manage securely across any global enterprise.

- Flexible digital twin deployment – Enrich existing systems through hybrid SaaS solutions to create an industrial digital twin that delivers fresh value opportunities.

Read the full article by Engineering News who unpacked this topic at IS³’s prestigious annual X-Change User Conference.

“This agreement enables clients to kindle a cultural shift towards anti-fragility and resilience. It accelerates their digital transformation journeys while ensuring alignment to global and regional marketing trends as well as technology. Being chosen for the Select Partnership program is not only a testament to the value that IS³ brings to AVEVA but also signifies the incredible progress that has been made in the reshaping of the industrial automation market”

Dion Govender – CEO, Digital Industries (Pty) Ltd

“An AVEVA Select partner can leverage the full breadth of our portfolio to empower customers as they double down on their digital strategies. Designed for our distributors, the unique AVEVA Select program helps them to optimize on opportunities and support customers to succeed in their digital transition. “We are pleased to welcome IS³ to the AVEVA Select family and look forward to developing and capitalizing on mutually beneficial growth strategies.”

Kerry Grimes – Head of Global Partners, AVEVA.

About IS³

About IS³

Driven by their ability to see the limitless potential of technology to empower people and transform businesses, IS³ provides industry software solutioning and support that enables individuals, teams, and businesses to move efficiently, seamlessly, and compliantly through their digital transformation journey. Their superior industrial software solutions include production, operations, production performance, manufacturing, intelligence, and business process management.

About AVEVA

About AVEVA

AVEVA is a global leader in industrial software, driving digital transformation and sustainability. By connecting the power of information and artificial intelligence with human insight, AVEVA enables teams to use their data to unlock new value. We call this Performance Intelligence. AVEVA’s comprehensive portfolio enables more than 20,000 industrial enterprises to engineer smarter, operate better and drive sustainable efficiency. AVEVA supports customers through a trusted ecosystem that includes 5,500 partners and 5,700 certified developers around the world. The company is headquartered in Cambridge, UK, with over 6,500 employees and 90 offices in over 40 countries.

About AVEVA Select

About AVEVA Select

The AVEVA Select program is designed for partners with full access to AVEVA’s comprehensive software portfolio, enabling them to help companies accelerate their digital transformation journey. AVEVA Select aligns to both market and technology trends, with programs designed to suit every product and solution specialization in the engineering and industrial segments. By leveraging the breadth of the AVEVA software portfolio, AVEVA Select partners can now help customers simplify design, optimize production, and maximize performance.

About IS³

About AVEVA

About AVEVA Select

About IS³

Driven by their ability to see the limitless potential of technology to empower people and transform businesses, IS³ provides industry software solutioning and support that enables individuals, teams, and businesses to move efficiently, seamlessly, and compliantly through their digital transformation journey. Their superior industrial software solutions include production, operations, production performance, manufacturing, intelligence, and business process management.

About AVEVA

AVEVA is a global leader in industrial software, driving digital transformation and sustainability. By connecting the power of information and artificial intelligence with human insight, AVEVA enables teams to use their data to unlock new value. We call this Performance Intelligence. AVEVA’s comprehensive portfolio enables more than 20,000 industrial enterprises to engineer smarter, operate better and drive sustainable efficiency. AVEVA supports customers through a trusted ecosystem that includes 5,500 partners and 5,700 certified developers around the world. The company is headquartered in Cambridge, UK, with over 6,500 employees and 90 offices in over 40 countries.

About AVEVA Select

The AVEVA Select program is designed for partners with full access to AVEVA’s comprehensive software portfolio, enabling them to help companies accelerate their digital transformation journey. AVEVA Select aligns to both market and technology trends, with programs designed to suit every product and solution specialization in the engineering and industrial segments. By leveraging the breadth of the AVEVA software portfolio, AVEVA Select partners can now help customers simplify design, optimize production, and maximize performance.

IS³’s Customer Success Stories

Speak to an Expert

Contact one of our highly qualified sales representatives to see how we can assist with maximising your potential!

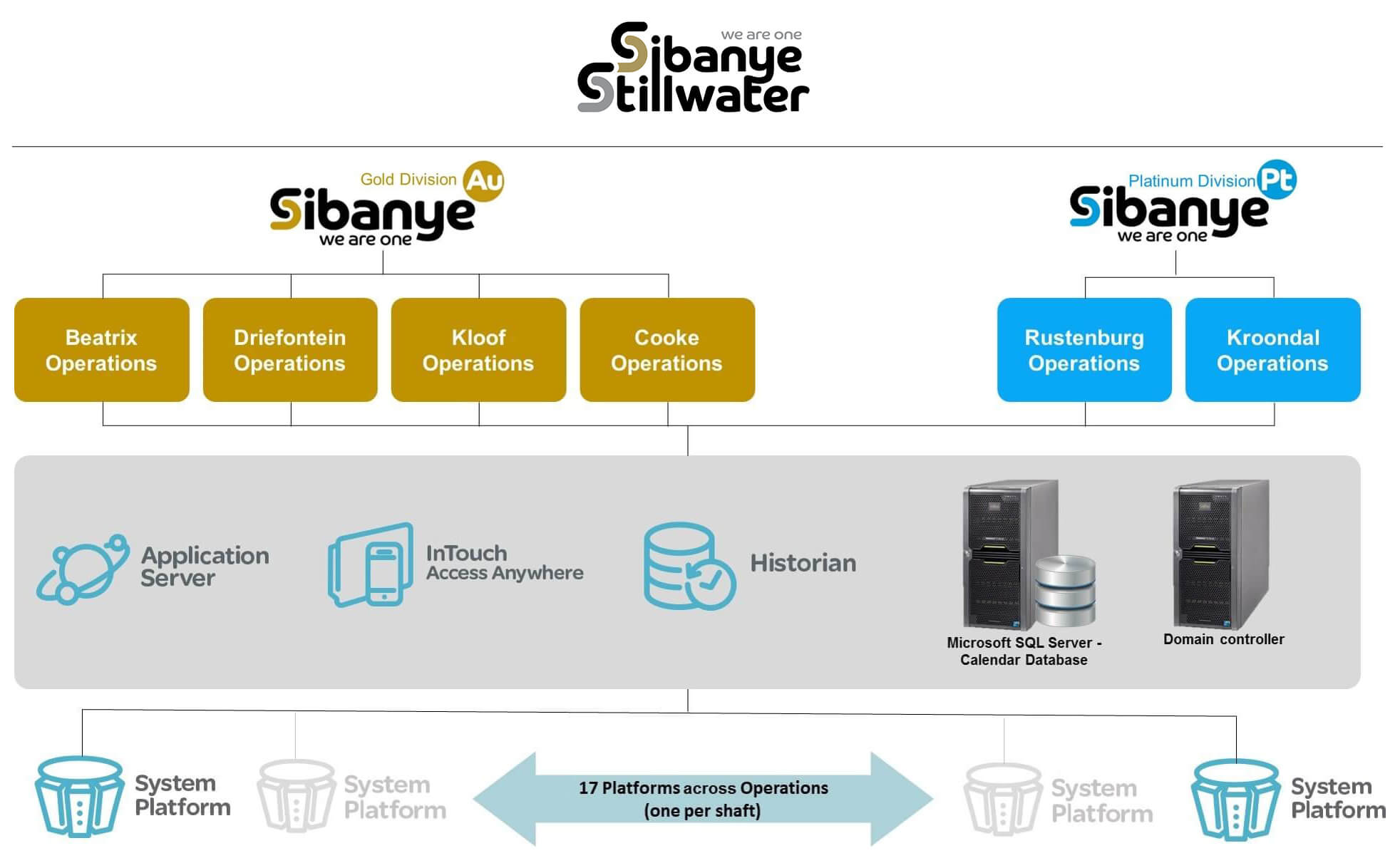

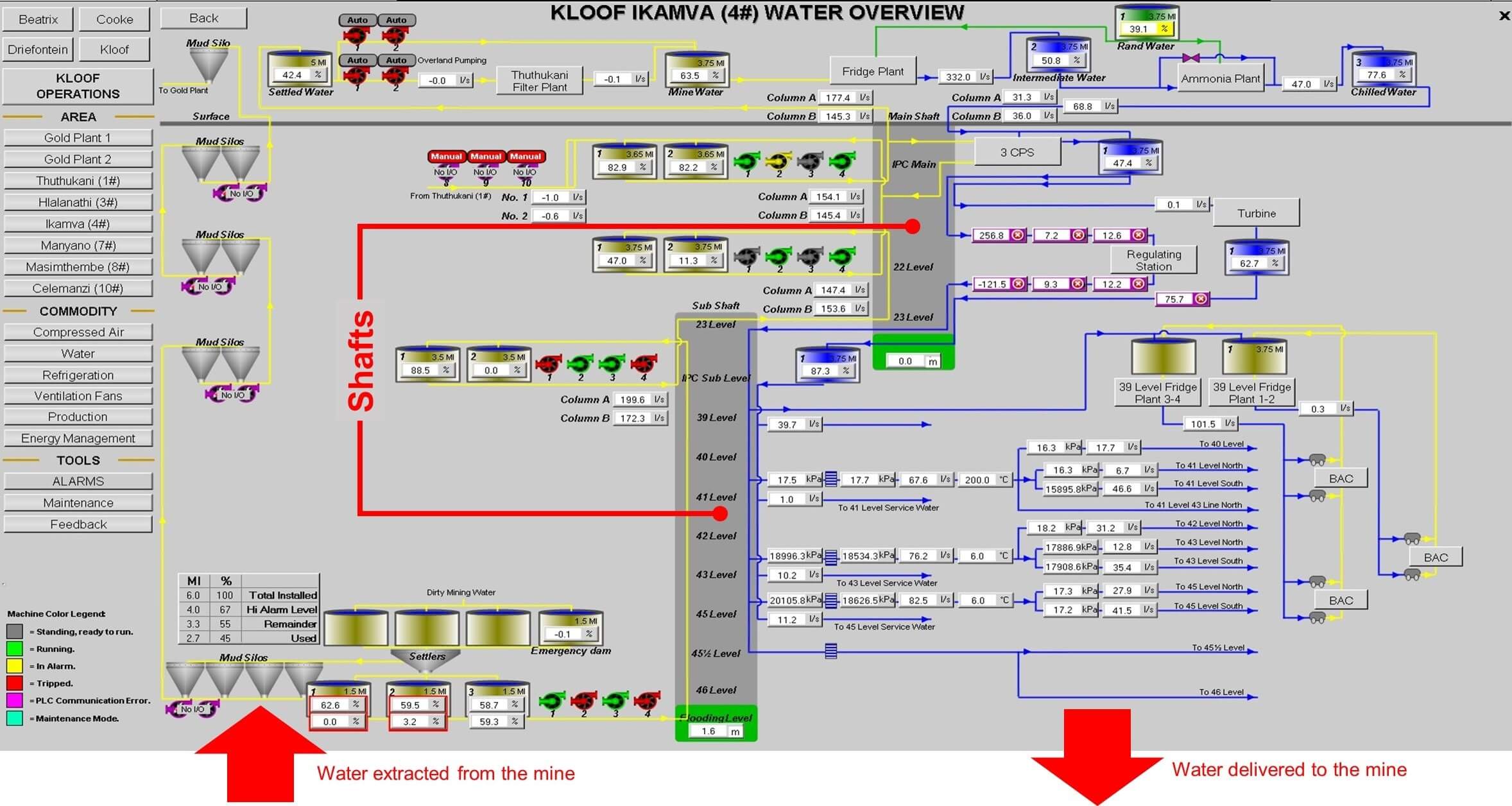

Enterprise-wide power management gives Sibanye-Stillwater’s mines the control they need

Goals

The implementation of an enterprise-wide power control solution that would meet Sibanye-Stillwater’s geographically-distributed needs

Challenges

- A singular application that spanned across and satisfied the needs of all Sibanye-Stillwater’s operations

- Perform automated load shifting

- Automated load clipping

- Centrally-managed control of the system, its equipment, and its schedules

- Continue operation in spite of network outages

Results

- The SCADA system is now a single application spanning across all of Sibanye-Stillwater’s operations

- Management has access to all data and information across the enterprise

- Centralised energy control

- Flexible system

- More deployments of this successful solution into new mines

Solutions & Products

- AVEVA System Platform

- AVEVA InTouch

- AVEVA Historian

- AUVESY-MDT AutoSave for System Platform

South Africa and Zimbabwe

A key cost factor in mining is electrical energy and Sibanye-Stillwater’s extensive, geographically-dispersed operations involved in the mining of gold, platinum and uranium, uses a lot of it. So much so that they saw the need for a holistic, enterprise-wide approach to the problem to replace the discrete and numerous solutions that had evolved over the years.

Background

Sibanye purchased a number of mines, each of which had evolved their own solution to the power management problem over many years. In fact, all these solutions added up to no less than 39 stand-alone applications across the company’s operations.

“Multiple energy control projects at the different operations resulted in many proprietary third-party systems being used for scheduling,” says P.J. Jansen van Rensburg, ICT Manager, Networks and Engineering Systems, Sibanye-Stillwater. “Any energy control schedule configuration was done in isolation of the others and their inflexibility caused some contradictory control problems such as different priorities seen from the perspective of the solution vendors – even at the same site. This resulted in management not having access to all applications and their information.”

But the problems didn’t end there. Sibanye-Stillwater’s production activities were not synchronised with Eskom’s tariff structures with regard to load shifting (moving the load demand to non-peak times) and load clipping (limiting the load to set limits). And lastly, there was no standardisation across all 32 SCADA systems in use at the time.

Implementation

Sibanye-Stillwater launched an initiative to implement an enterprise-wide power control module that would meet the following criteria:

Consist of a singular application that spanned across and satisfied the needs of all Sibanye-Stillwater’s operations

Perform automated load shifting

Maintain usage within limits at all times (automated load clipping)

Provide centrally-managed control of the system, its equipment and its schedules

Continue operation in spite of network outages

“We chose a decentralised infrastructure model, which meant that, in the event of a hardware failure, only the local site would be affected while each Sibanye operation, shaft and PLC would be able to run independently in case of a communication failure,” says van Rensburg. “The solution that ticked all the boxes was [AVEVA’s] System Platform.”

“To better understand what the total power control module needed to do, it’s important to understand Eskom’s two-part tariff system,” says van Rensburg. “This consists of Load Shifting which means scheduling machinery to either stop working altogether or run unloaded during Eskom’s peak periods (18:00 to 20:00 in summer and 17:00 to 19:00 in winter – 2.5 times the rate for non-peak consumption). Then there’s Load Clipping which is done by unloading machinery during Eskom’s peak and standard tariff periods as per set targets.”

So schedules were created, configured and activated to cope with Load Shifting while targets were set and algorithms created and deployed to handle the Load Clipping aspect of power control. “Because of its real-time nature, we still can’t do Load Clipping during network failure,” explains van Rensburg. “But Load Shifting is no longer a problem because a register for the next 20 operations is programmed into the PLC every few seconds which means that it can continue to independently shift loads for up to a week if necessary.”

“Standardisation is crucial to operator efficiency it they change plants but it also provides a standardised communication ‘language’ and understanding between everyone involved who all have access to this production information. This lets them benchmark and compare their accomplishments to other plants because they all share a common standard for performance,” says van Rensburg.

Results

- The current SCADA system is now a single application spanning across all of Sibanye-Stillwater’s operations.

- Management now has access to all data and information across the enterprise.

- All energy control projects can be controlled centrally and projects are underway to move to central control.

- This system is flexible enough to allow for continuous improvements and savings.

- Sibanye has acquired more mines and the system is being successfully implemented into these new ventures

About Sibanye-Stillwater

Sibanye-Stillwater owns and operates high-quality gold and platinum operations in South Africa – consolidated into one Group with one vision and strategy. The long-term success of Sibanye-Stillwater as a business and as a responsible corporate citizen is dependent on all stakeholders working together as one.

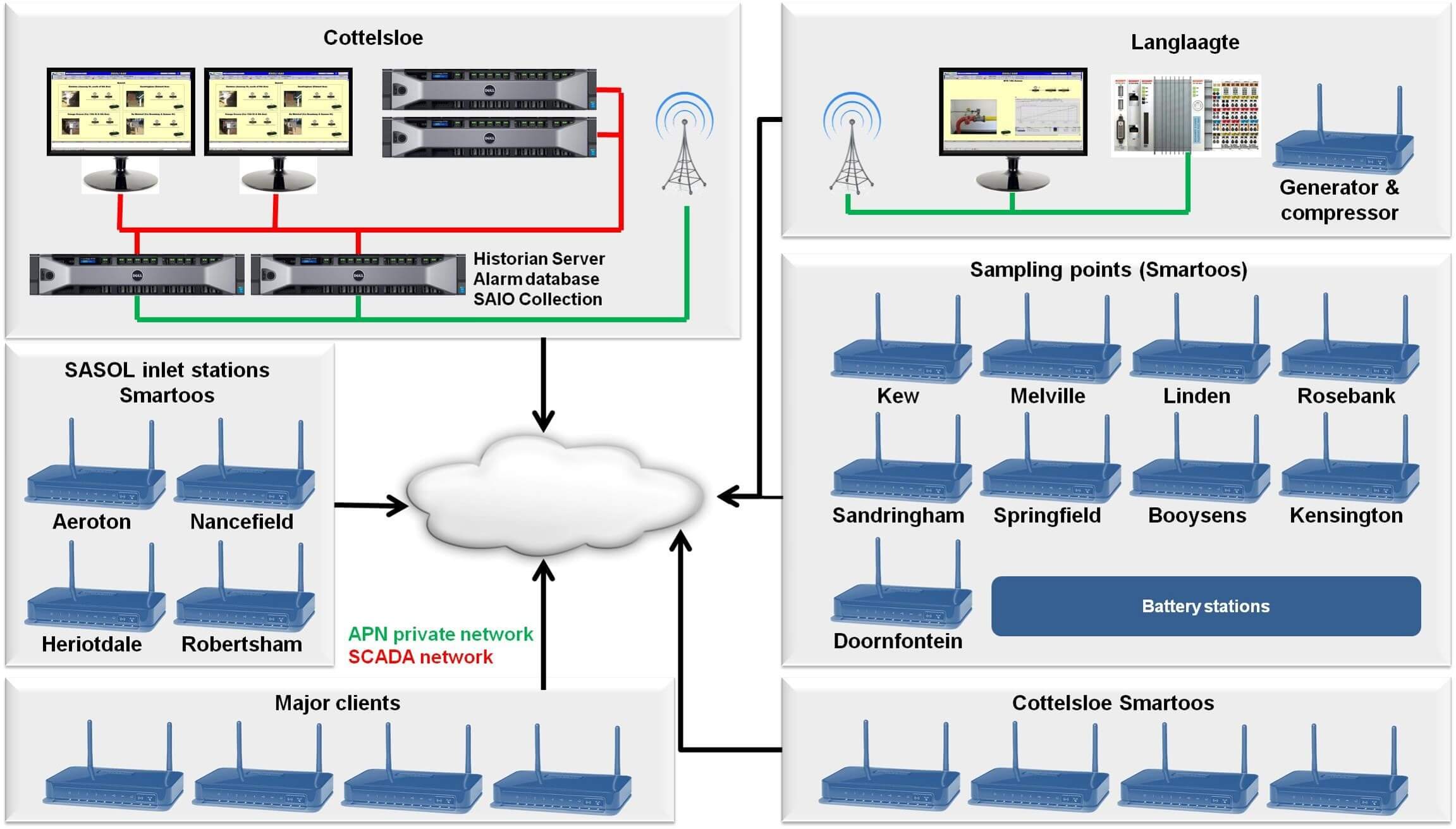

Egoli Gas saves 95% of personnel time and energy through automated network monitoring

Goals

- Meet customer needs while looking after network safety

- Reduce meter reading time and costs

- Improve knowledge of imported and delivered gas as well as network status in real time

Challenges

How to implement GSM-based data acquisition technology at remote locations with power and security problems

Results

- Considerable reduction in personnel time and travelling costs

- Accurate monitoring of pressures to look after customer requirements and the network’s safety

- Reduction in maintenance personnel and effort

- Accurate reconciliation of imported and exported gas

- Speedy response to faults/issues

- Real-time knowledge of network health and status

- The system will be expanded to detect leaks and illegal taps

Solutions & Products

- System Platform

- Historian

- Historian Client

- InTouch

Johannesburg, Gauteng, South Africa

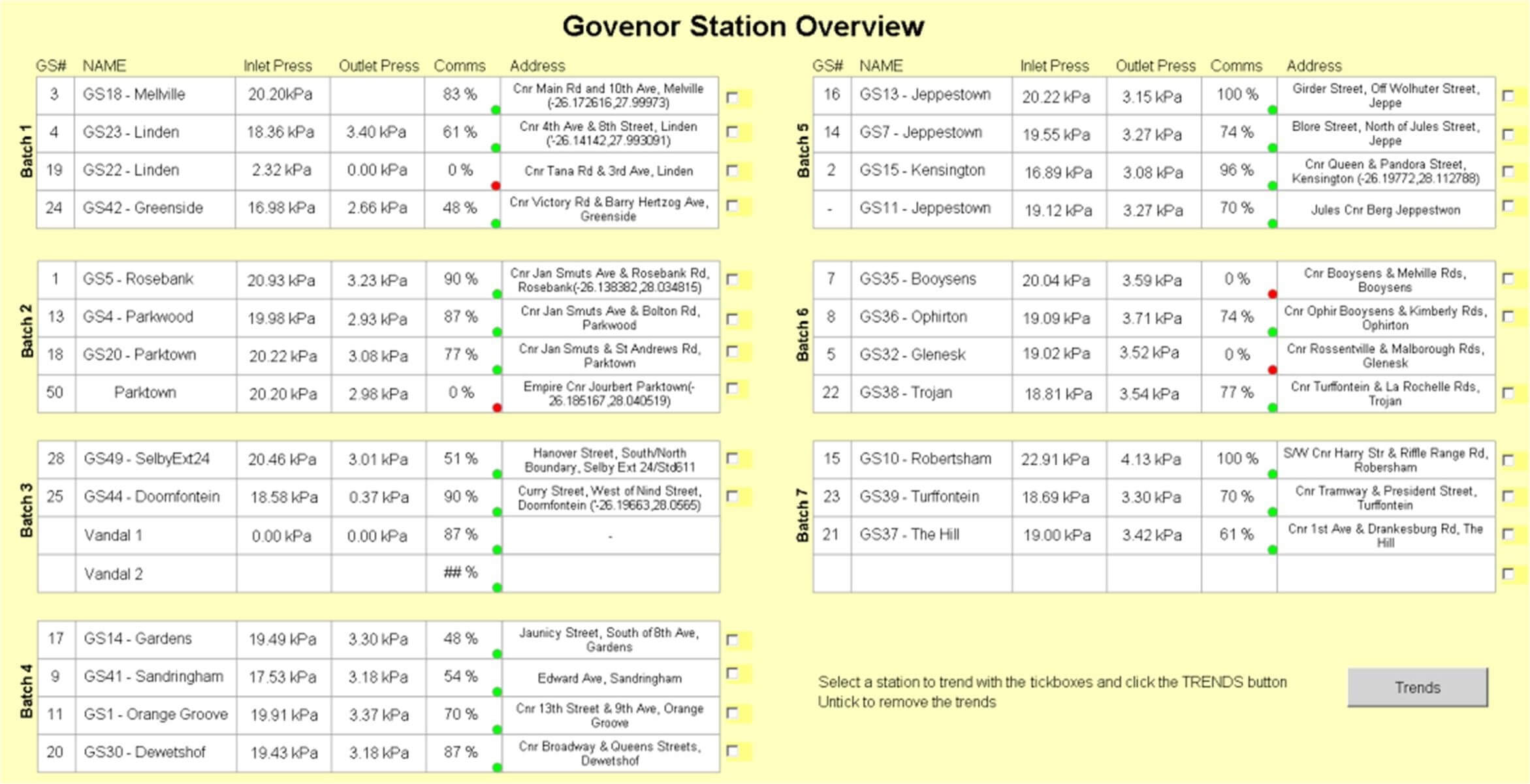

With a “shop floor” covering the greater Johannesburg metropolitan area, Egoli Gas had an understandable problem reading their meters and getting a grip on the true status of their vast pipe network. Today, manual data collection is a thing of the past and Egoli Gas can do a better job of looking after its customers by meeting their needs in real time.

Background

Prior to the installation of this new system, Egoli Gas personnel would drive to 7200 gas meters in a 1800 km-long network covering a large portion of the greater Johannesburg metropolitan area, They would log consumption data for processing in Excel from which very basic reports were generated for management.

This entirely manual process was prone to human error, unsynchronised meter readings and further time delays in generating the reports. The result was an inefficient operation and delayed response to issues affecting gas delivery to Egoli Gas’ clients.

“As a utility company with many important customers, our challenges were numerous,” says Emmanuel Matodzi, Projects and Planning Engineer at Egoli Gas. “How do we read all the 7500 meters in our network or how do we ensure that none of the sectors in our network is being starved of gas or is experiencing low pressure – especially in times of sudden demand from our clients who use gas for power generation during power load shedding?”

But that’s only half the story. At any moment in time, Egoli Gas couldn’t readily reconcile the volume of gas they bought from SASOL with the amount supplied to their customers until the tedious and time-consuming process of manual data collection was completed – so reducing the time and cost of personnel travelling their vast network had to be addressed.

And the list goes on: How could Egoli Gas be proactive in pre-empting unwanted high pressures in their ageing network which isn’t only undesirable for the network but especially for their customers whose equipment may be designed to cope with 3 rather than 25 kPa? How can the company address the problem of detecting theft and leaks? Then there was the real need to know at all times how much gas capacity was in reserve as well as the health of the entire network.

This was all about bringing decades-old but vital energy technology into the 21st century with all its attendant problems and challenges. What’s more, whatever solution was chosen could not rely on human intervention and had to be entirely reliable since the profitability of Egoli Gas and the satisfaction of its customers depended on it.

Egoli Gas took a bold decision to address all these issues once and for all. Their goal was to develop a gas network monitoring solution using solar-powered GSM data acquisition technology and to log the data automatically in order to provide reports on gas distribution and consumption – all in real time while also addressing the issues of power availability at remote locations as well as that of vandal-proofing.

Implementation

Egoli Gas selected AVEVA-certified system integrator Systems Anywhere for the implementation of this landmark project who decided to build on Egoli Gas’ existing Wonderware-based industrial information infrastructure.

Systems Anywhere designed a cost-effective solar-powered, vandal-proof logging station (Smartoos) for use at all measuring nodes to log gas volume, pressure and temperature in order to determine the gas supply conditions at all these delivery points. Readings are transmitted via private APN every 2 minutes to the Cottesloe “Starfish” with a Port-Forwarding configuration.

“This alone resulted in huge savings in terms of personnel and travelling costs as well as time,” says Matodzi. “In fact, we estimate that time and cost savings to be about 95% with 100% improvement in the quality of data – not only in its accuracy but also in its near-real-time delivery. The system also provides every department with the information they need. For example, account managers now know precisely what their key accounts are doing and can advise them accordingly and our own accountants know precisely how much gas we’re importing and distributing.”

The first glimpse into what’s happening in Egoli Gas’ network is the overview of its 24 governor stations whose job it is to reduce mainline pressure to what consumers need – like a step-down transformer in an electrical network. This InTouch screen provides a concise view of current conditions and alarms. The elimination of all manual data collection lets Egoli Gas personnel concentrate on improving customer service through the early and rapid detection and identification of irregularities in the gas distribution network before they become a problem for end-users. This is especially applicable to those users who use gas for power generation.

“This information also allows us to look after our ageing pipe network to ensure that pressure doesn’t exceed 25 kPa but is maintained above 16 kPa on the high-pressure mains,” says Matodzi. “This level of data acquisition and analysis means that Egoli Gas personnel can focus their experience and expertise on real issues and on maintenance rather than data collection. “

About Egoli Gas (Pty) Ltd

Egoli Gas is a natural gas reticulator based in Johannesburg and servicing more than 7 500 domestic, central water heating, commercial and industrial businesses in the Johannesburg area. The company operates an 1800 km network dating back to the company’s origin in 1892.

The service offers environmentally-friendly, safe, reliable and energy-efficient natural gas. The company’s commitment to their customers’ energy-efficient, low-carbon lifestyle ensures an uninterrupted flow of natural gas ready to use when it’s needed, safely.

Egoli Gas acquires natural gas from Sasol which is stored at a secure facility in Langlaagte where it is carefully monitored and controlled.

The gas is reticulated to Egoli Gas’ Cottesloe premises where it’s stored in low pressure holders before being reticulated to homes and businesses across the city.

For domestic use, Egoli Gas is located in many of the more established Johannesburg suburbs; however, the pipeline extends even further for its commercial and industrial customers.