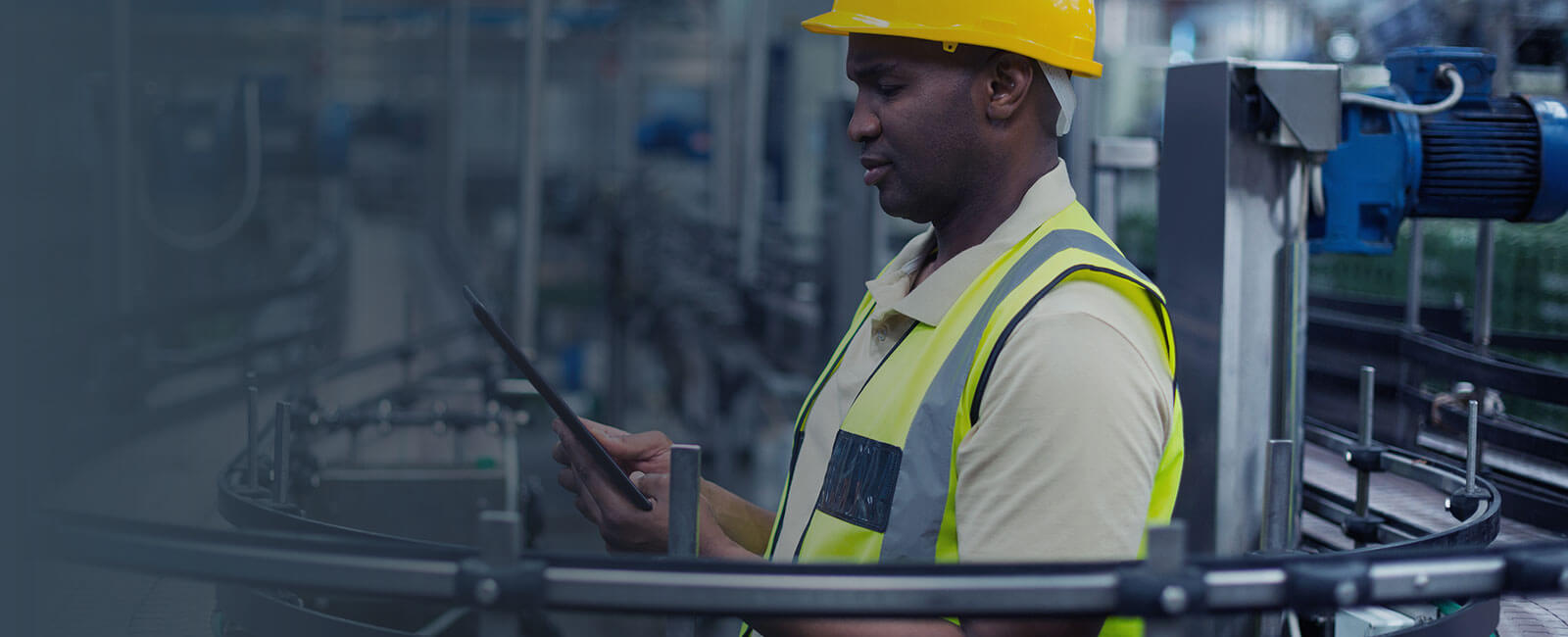

As citizens, we depend upon the infrastructure provided by transportation networks, municipal operations, buildings, facilities and campuses, public utilities and Smart Cities for just about everything. The more efficiently they are run, the greater their contribution to increasing the health, safety and well-being of everyone who uses them.

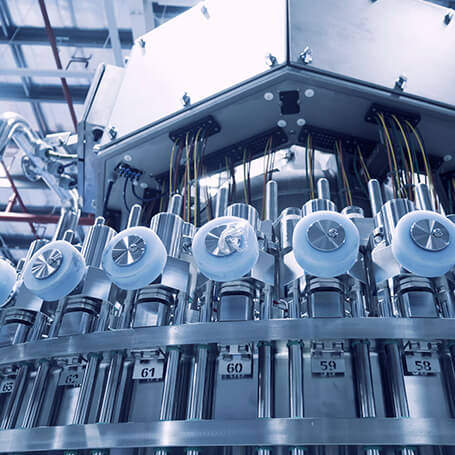

Addressing critical infrastructure challenges such as urbanisation, overpopulation, pollution, congestion and security require complex networks that have to operate efficiently, safely and effectively. However, a rapid increase in sub-systems, hardware devices, connected and manually intensive data sources, as well as operational silos, ask for a different approach to solving the interconnected challenges which infrastructure operators are so often confronted with.

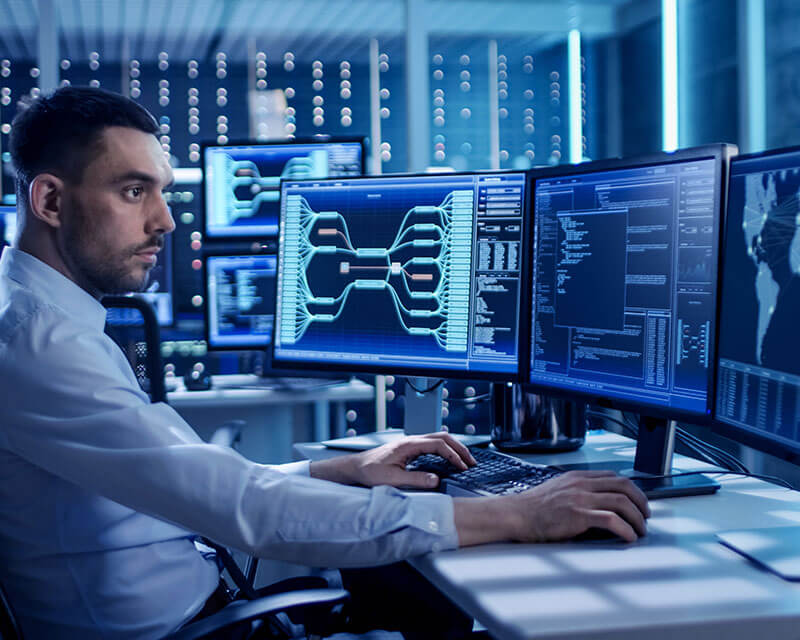

To Systems Engineers, systems thinking is not a novel concept. At the heart of any well-designed monitoring and control system lies a deep understanding of the way components interact, interrelate and interdepend to form a complex and unified system. In the complex world of smart infrastructure, the necessity for systems thinking has never been more crucial.

From Smart Cities to campus administration, integrated traffic control to smart airport operations – in order to derive pertinent operational insights, a single view of the interaction between people, processes and technology is a necessity.