Accelerate time to value with AVEVA Industrial Cloud Platform

Enable the connected digital landscape and break down boundaries with an open cloud platform optimised for unlocking industrial insights in real-time.

Advantages of industrial hybrid SaaS solutions:

- Accelerate time to value – Adopt strategic industrial hybrid SaaS that are easy to deploy, access, and manage securely across any global enterprise.

- Flexible digital twin deployment – Enrich existing systems through hybrid SaaS solutions to create an industrial digital twin that delivers fresh value opportunities.

Read the full article by Engineering News who unpacked this topic at IS³’s prestigious annual X-Change User Conference.

Accelerate time to value with AVEVA Industrial Cloud Platform

Enable the connected digital landscape and break down boundaries with an open cloud platform optimised for unlocking industrial insights in real-time.

Advantages of industrial hybrid SaaS solutions:

- Accelerate time to value – Adopt strategic industrial hybrid SaaS that are easy to deploy, access, and manage securely across any global enterprise.

- Flexible digital twin deployment – Enrich existing systems through hybrid SaaS solutions to create an industrial digital twin that delivers fresh value opportunities.

Read the full article by Engineering News who unpacked this topic at IS³’s prestigious annual X-Change User Conference.

Accelerate time to value with AVEVA Industrial Cloud Platform

Enable the connected digital landscape and break down boundaries with an open cloud platform optimised for unlocking industrial insights in real-time.

Advantages of industrial hybrid SaaS solutions:

- Accelerate time to value – Adopt strategic industrial hybrid SaaS that are easy to deploy, access, and manage securely across any global enterprise.

- Flexible digital twin deployment – Enrich existing systems through hybrid SaaS solutions to create an industrial digital twin that delivers fresh value opportunities.

Read the full article by Engineering News who unpacked this topic at IS³’s prestigious annual X-Change User Conference.

Accelerate time to value with AVEVA Industrial Cloud Platform

Enable the connected digital landscape and break down boundaries with an open cloud platform optimised for unlocking industrial insights in real-time.

Advantages of industrial hybrid SaaS solutions:

- Accelerate time to value – Adopt strategic industrial hybrid SaaS that are easy to deploy, access, and manage securely across any global enterprise.

- Flexible digital twin deployment – Enrich existing systems through hybrid SaaS solutions to create an industrial digital twin that delivers fresh value opportunities.

Read the full article by Engineering News who unpacked this topic at IS³’s prestigious annual X-Change User Conference.

“This agreement enables clients to kindle a cultural shift towards anti-fragility and resilience. It accelerates their digital transformation journeys while ensuring alignment to global and regional marketing trends as well as technology. Being chosen for the Select Partnership program is not only a testament to the value that IS³ brings to AVEVA but also signifies the incredible progress that has been made in the reshaping of the industrial automation market”

Dion Govender – CEO, Digital Industries (Pty) Ltd

“An AVEVA Select partner can leverage the full breadth of our portfolio to empower customers as they double down on their digital strategies. Designed for our distributors, the unique AVEVA Select program helps them to optimize on opportunities and support customers to succeed in their digital transition. “We are pleased to welcome IS³ to the AVEVA Select family and look forward to developing and capitalizing on mutually beneficial growth strategies.”

Kerry Grimes – Head of Global Partners, AVEVA.

About IS³

About IS³

Driven by their ability to see the limitless potential of technology to empower people and transform businesses, IS³ provides industry software solutioning and support that enables individuals, teams, and businesses to move efficiently, seamlessly, and compliantly through their digital transformation journey. Their superior industrial software solutions include production, operations, production performance, manufacturing, intelligence, and business process management.

About AVEVA

About AVEVA

AVEVA is a global leader in industrial software, driving digital transformation and sustainability. By connecting the power of information and artificial intelligence with human insight, AVEVA enables teams to use their data to unlock new value. We call this Performance Intelligence. AVEVA’s comprehensive portfolio enables more than 20,000 industrial enterprises to engineer smarter, operate better and drive sustainable efficiency. AVEVA supports customers through a trusted ecosystem that includes 5,500 partners and 5,700 certified developers around the world. The company is headquartered in Cambridge, UK, with over 6,500 employees and 90 offices in over 40 countries.

About AVEVA Select

About AVEVA Select

The AVEVA Select program is designed for partners with full access to AVEVA’s comprehensive software portfolio, enabling them to help companies accelerate their digital transformation journey. AVEVA Select aligns to both market and technology trends, with programs designed to suit every product and solution specialization in the engineering and industrial segments. By leveraging the breadth of the AVEVA software portfolio, AVEVA Select partners can now help customers simplify design, optimize production, and maximize performance.

About IS³

About AVEVA

About AVEVA Select

About IS³

Driven by their ability to see the limitless potential of technology to empower people and transform businesses, IS³ provides industry software solutioning and support that enables individuals, teams, and businesses to move efficiently, seamlessly, and compliantly through their digital transformation journey. Their superior industrial software solutions include production, operations, production performance, manufacturing, intelligence, and business process management.

About AVEVA

AVEVA is a global leader in industrial software, driving digital transformation and sustainability. By connecting the power of information and artificial intelligence with human insight, AVEVA enables teams to use their data to unlock new value. We call this Performance Intelligence. AVEVA’s comprehensive portfolio enables more than 20,000 industrial enterprises to engineer smarter, operate better and drive sustainable efficiency. AVEVA supports customers through a trusted ecosystem that includes 5,500 partners and 5,700 certified developers around the world. The company is headquartered in Cambridge, UK, with over 6,500 employees and 90 offices in over 40 countries.

About AVEVA Select

The AVEVA Select program is designed for partners with full access to AVEVA’s comprehensive software portfolio, enabling them to help companies accelerate their digital transformation journey. AVEVA Select aligns to both market and technology trends, with programs designed to suit every product and solution specialization in the engineering and industrial segments. By leveraging the breadth of the AVEVA software portfolio, AVEVA Select partners can now help customers simplify design, optimize production, and maximize performance.

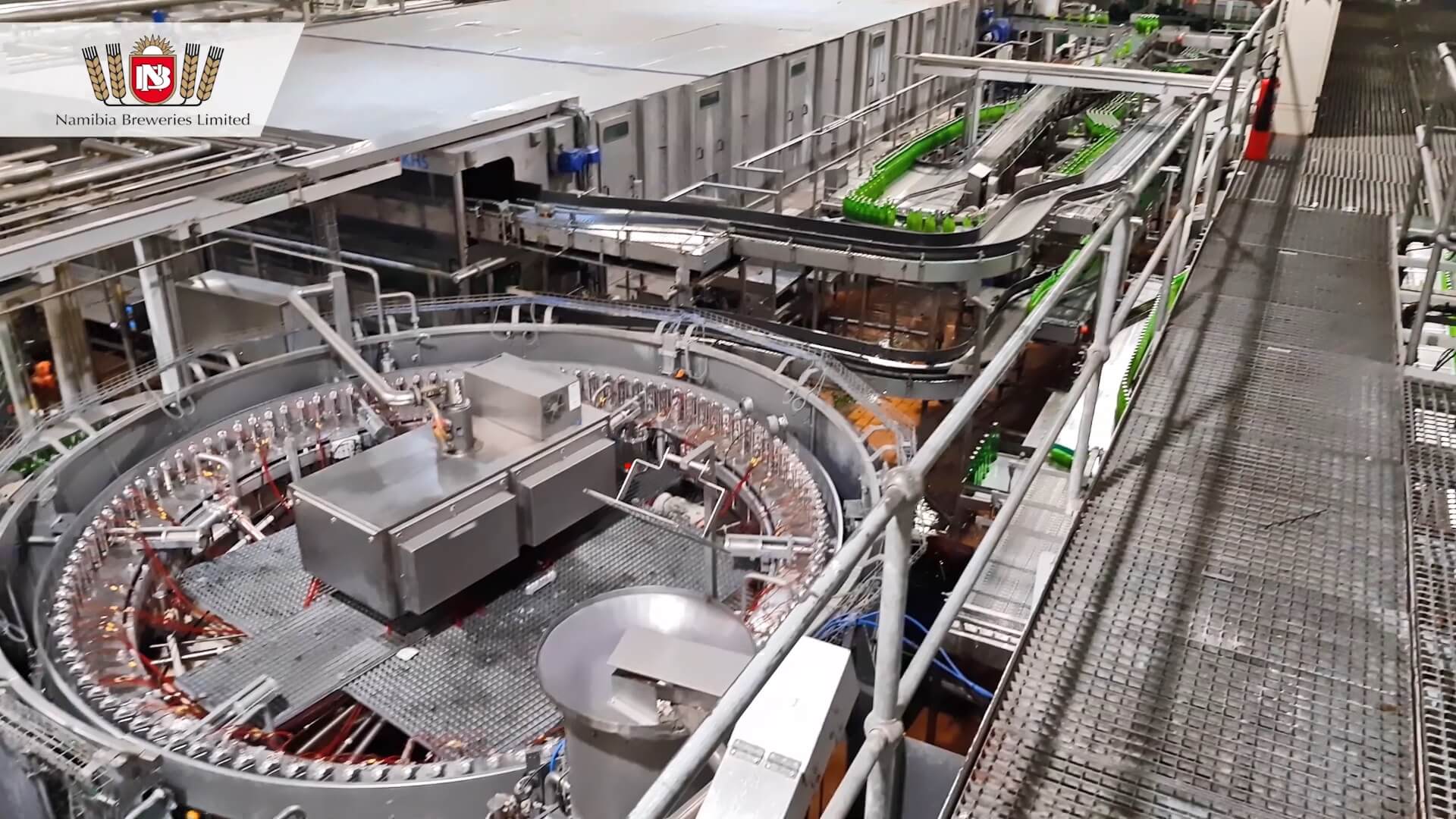

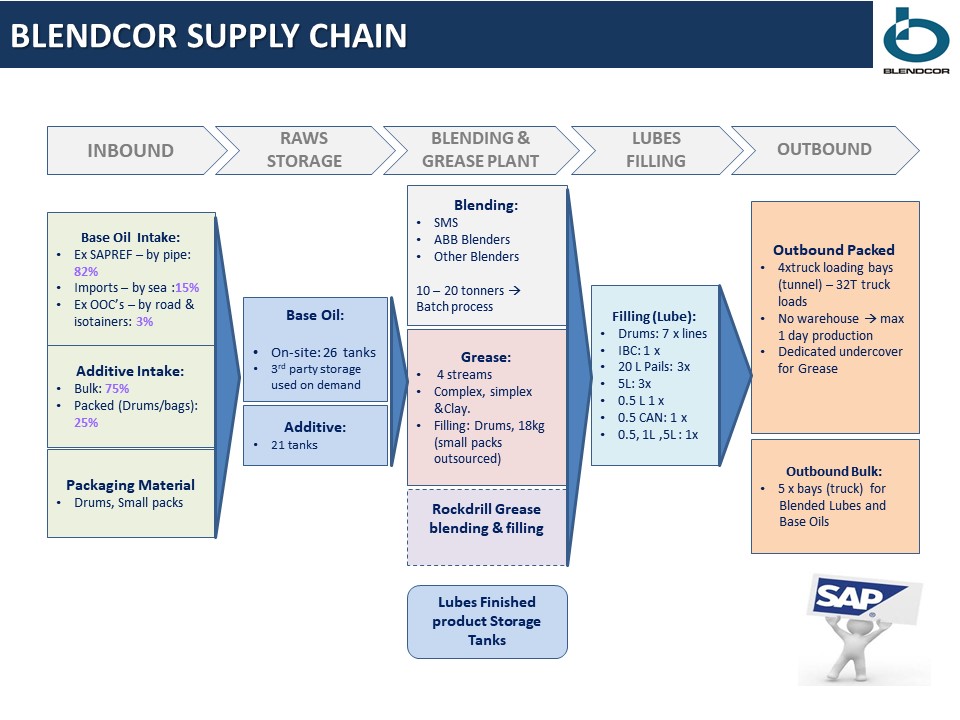

Blendcor – control system upgrade within grease plant

Blendcor implemented a control system upgrade within their grease plant. Incorporation of a

customised situational awareness library based on AVEVA standards have improved operator

and engineering efficiency to further protect the sites assets.

Background

The site, comprising approximately 53 000m2, is situated in Island View, Durban, with its frontage on 135 Honshu Road. The property is leased from the Transnet National Ports Authority and falls under the jurisdiction of the National Key Points Act. Both shareholders, Shell and BP, are part of the larger international organisations and as such Blendcor is considered an operating unit of these international companies. The performance of Shell and BP internationally is measured by the cumulative performances of the individual operating units. Hence, Blendcor is obliged to conform to the requirements of Shell and BP international standards in addition to the statutory, local, regional, and national requirements. Blendcor is committed to achieving business excellence, through attaining the best possible business results.

Business Challenges

Due to the limitations of its existing legacy monitoring and control infrastructure within Blendcor’s grease plant section there became a requirement to have an immediate upgrade strategy to improve the grease plant efficiency and lay the foundation for future expansions. Specifically, the following problem areas were identified:

- Aging and unsupported control systems. Blendcor’s aging control system hardware and software resulted in lack of spare availability and support.

- Compliance: legacy applications were only compatible with operating systems with completed life cycles, which made it difficult to comply Blendcor’s IT requirements.

- Standards: No standardisation within the control programs and SCADA caused fault finding to be time consuming and inefficient.

- Limited expansion capability with legacy equipment: the current control systems did not allow for the growth taking into consideration Blendcor’songoing efficiency improving projects.

Blendcor identified an upgrade strategy that focused on three major areas:

- Utilising the latest server hardware and operating systems to transition from being on a workgroup network to the Blendcor domain.

- Replace aging control system hardware and rewriting the software program using standards like that used within their blending plant.

- Replace the standalone lnTouch 2012 system and replace it with AVEVA System Platform utilising modern standards.

The upgrade strategy required input form all major shareholders including but not limited to management, production personnel, C&I personnel and most importantly the operators.

The following upgrade strategy was chosen:

- Aging and unsupported control systems: A control system switchover to the supported Mod icon M580 controller.

- Compliance: Installation of the latest AVEVA System Platform supported by Windows Server 2016 in a virtualised environment.

- Standards: Control program standards transferred from the blend plant to be utilised in the grease plant and the use of a Blendcor Situational Awareness Library built on the standards developed by AVEVA.

Blendcor’s project, engineering and production departments were integral to the successful deployment of the new system. The strategy implementation took months of planning and investigations.

Investigation 1 – Identifying the plant layout using the P&IDs as reference. It was found that there were many changes, and the current system did not reflect these changes.

Investigation 2 – Identifying the current control program operation which was made challenging due to no program comments or control philosophies being present.

Investigation 3 – Operator process challenges.

Planning Stage 1 – Introducing the visualisation and operational requirements from operations which included multiple thin slice demos and the introduction of the new situational awareness library.

Planning Stage 2 – Introducing the new control program standards based on the blend plant control programming standards.

Results of the upgrade

The new control system implementation was done in parallel with old current system and this allowed for quick transition back to the old system after testing. All testing was done in a live environment with Blendcor supplying ingredient batches for testing purposes. The implementation consisted of 3

test deployments and a 4th final deployment. Blendcor’s client demands meant that deployments could only be achieved during planned shutdowns, which consisted of multiple holiday breaks including a December shutdown.

The result of the successful upgrade:

- Supervisory Control System: The new OMI applications created using situational awareness allows the operators to identify faults that were previously not visualised accurately.

- Compliance: The incorporation of the AVEVA System Platform within a virtualised environment allows for the IT department to implement crucial security updates.

- Software Lifespan: Subscription to AVEVA’s Customer First Support plan ensures that Blendcor always has the latest software updates available for incorporation.

- Hardware Lifespan: Installation of the latest Modicon M580 CPU allows for an extended hardware lifecycle.

- Expansion: The AVEVA System Platform installation allows Blendcor to incorporate other plant sections and areas into one centralised control system at a rapid rate.

IS³’s Customer Success Stories