AVEVA aiming to drive sustainability by helping industries digitally transform

As an AVEVA Select partner we are proud to be the sole AVEVA distributor for the sub-Saharan region and drive the approach AVEVA is taking when it comes to sustainability.

At AVEVA, sustainability has never been higher on the agenda! Our partner is taking actions to embed sustainability into our operations and our core business strategy. They are committed to leading sustainable innovation and to work in partnership with others to make a more just, net-zero world a reality for the next generation.

They will manage sustainability through the lens of their technology handprint, operational footprint, and inclusive culture. This approach was delivered to our region in Southern Africa at our Annual X-Change User Conference that took place in May 2022.

Our media partner, Engineering News, covered this topic in further detail in an article below:

AVEVA aiming to drive sustainability by helping industries digitally transform

As an AVEVA Select partner we are proud to be the sole AVEVA distributor for the sub-Saharan region and drive the approach AVEVA is taking when it comes to sustainability.

At AVEVA, sustainability has never been higher on the agenda! Our partner is taking actions to embed sustainability into our operations and our core business strategy. They are committed to leading sustainable innovation and to work in partnership with others to make a more just, net-zero world a reality for the next generation.

They will manage sustainability through the lens of their technology handprint, operational footprint, and inclusive culture. This approach was delivered to our region in Southern Africa at our Annual X-Change User Conference that took place in May 2022.

Our media partner, Engineering News, covered this topic in further detail in an article below:

“This agreement enables clients to kindle a cultural shift towards anti-fragility and resilience. It accelerates their digital transformation journeys while ensuring alignment to global and regional marketing trends as well as technology. Being chosen for the Select Partnership program is not only a testament to the value that IS³ brings to AVEVA but also signifies the incredible progress that has been made in the reshaping of the industrial automation market”

Dion Govender – CEO, Digital Industries (Pty) Ltd

“An AVEVA Select partner can leverage the full breadth of our portfolio to empower customers as they double down on their digital strategies. Designed for our distributors, the unique AVEVA Select program helps them to optimize on opportunities and support customers to succeed in their digital transition. “We are pleased to welcome IS³ to the AVEVA Select family and look forward to developing and capitalizing on mutually beneficial growth strategies.”

Kerry Grimes – Head of Global Partners, AVEVA.

About IS³

About IS³

Driven by their ability to see the limitless potential of technology to empower people and transform businesses, IS³ provides industry software solutioning and support that enables individuals, teams, and businesses to move efficiently, seamlessly, and compliantly through their digital transformation journey. Their superior industrial software solutions include production, operations, production performance, manufacturing, intelligence, and business process management.

About AVEVA

About AVEVA

AVEVA is a global leader in industrial software, driving digital transformation and sustainability. By connecting the power of information and artificial intelligence with human insight, AVEVA enables teams to use their data to unlock new value. We call this Performance Intelligence. AVEVA’s comprehensive portfolio enables more than 20,000 industrial enterprises to engineer smarter, operate better and drive sustainable efficiency. AVEVA supports customers through a trusted ecosystem that includes 5,500 partners and 5,700 certified developers around the world. The company is headquartered in Cambridge, UK, with over 6,500 employees and 90 offices in over 40 countries.

About AVEVA Select

About AVEVA Select

The AVEVA Select program is designed for partners with full access to AVEVA’s comprehensive software portfolio, enabling them to help companies accelerate their digital transformation journey. AVEVA Select aligns to both market and technology trends, with programs designed to suit every product and solution specialization in the engineering and industrial segments. By leveraging the breadth of the AVEVA software portfolio, AVEVA Select partners can now help customers simplify design, optimize production, and maximize performance.

About IS³

About AVEVA

About AVEVA Select

About IS³

Driven by their ability to see the limitless potential of technology to empower people and transform businesses, IS³ provides industry software solutioning and support that enables individuals, teams, and businesses to move efficiently, seamlessly, and compliantly through their digital transformation journey. Their superior industrial software solutions include production, operations, production performance, manufacturing, intelligence, and business process management.

About AVEVA

AVEVA is a global leader in industrial software, driving digital transformation and sustainability. By connecting the power of information and artificial intelligence with human insight, AVEVA enables teams to use their data to unlock new value. We call this Performance Intelligence. AVEVA’s comprehensive portfolio enables more than 20,000 industrial enterprises to engineer smarter, operate better and drive sustainable efficiency. AVEVA supports customers through a trusted ecosystem that includes 5,500 partners and 5,700 certified developers around the world. The company is headquartered in Cambridge, UK, with over 6,500 employees and 90 offices in over 40 countries.

About AVEVA Select

The AVEVA Select program is designed for partners with full access to AVEVA’s comprehensive software portfolio, enabling them to help companies accelerate their digital transformation journey. AVEVA Select aligns to both market and technology trends, with programs designed to suit every product and solution specialization in the engineering and industrial segments. By leveraging the breadth of the AVEVA software portfolio, AVEVA Select partners can now help customers simplify design, optimize production, and maximize performance.

IS³’s Customer Success Stories

Speak to an Expert

Contact one of our highly qualified sales representatives to see how we can assist with maximising your potential!

L’Oréal South Africa implements a virtualised Manufacturing Operations Management system

Goals

- Mitigate the risk posed by unsupported legacy systems

- Modernise and streamline the manufacturing process

- Consolidate the various server platforms required for the manufacturing process

Solutions and Products

- System Platform

- Historian

- InTouch

- InBatch

Challenges

- Reverse engineering the existing InControl system

- Transporting the well-designed S88 standards to the new PLC

Results

- Business risk was reduced

- Production information is available to more people

- System design and reliability was improved

- Reduced hardware support through the virtualisation of the manufacturing servers

Midrand, Gauteng, South Africa

Quality, innovation and, above all, consistency, are the hallmarks of L’Oréal products – and that’s why accurate batch management is of such importance to the company that has led the cosmetics industry for more than a century. But there’s more to quality production than excellent batch management.

Background

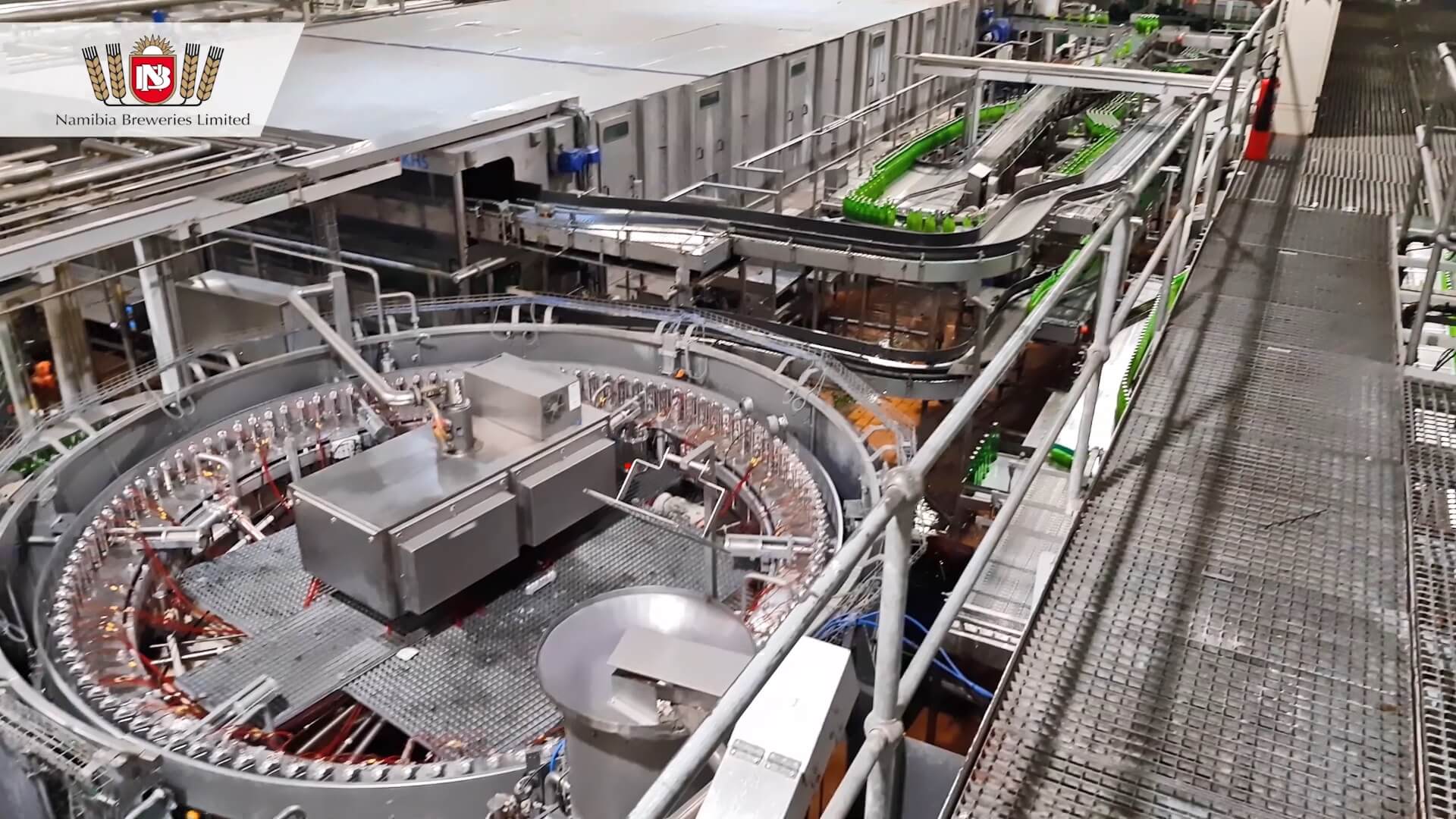

Production at L’Oréal’s Midrand manufacturing plant depends on the operation of two “skids”. A skid is an assembly of a group of modular pieces into a single unit. This includes mixing tanks, storage tanks and CIP systems among others. All tanks, pumps, valves, heat exchangers, instrumentation and controls are factory-assembled and tested prior to shipment.

Simply put, a skid is an entire “process system in a box.” It arrives at the processing facility ready to be plugged into the power and utilities with little on-site construction required. There is very little production downtime and unforeseen start-up delays can be discovered and corrected before the equipment ever leaves the manufacturing facility.

Prior to this project, each skid had software and hardware. There were different standards for each skid, the software was past its end-of-life cycle, the hardware was obsolete and overloaded and there was no disaster-recovery plan.

So the project goals focused on mitigating the risk posed by unsupported legacy systems, modernising and streamlining the manufacturing process and consolidating the various server platforms required for production.

Implementation

For L’Oréal, the way forward consisted of selecting an AVEVA systems integrator and implementing some important upgrade initiatives. The chosen system integrator was Control Systems Integration (CSI) and the upgrade initiatives included:

Assigning dedicated server roles after a strategic decision was made to implement virtual servers. Virtualisation was acknowledged to reduce infrastructure costs while increasing maintainability and flexibility.

L’Oréal already had an investment in Wonderware (now AVEVA) solutions including InTouch, InControl, InBatch (including extensive training) and InSQL (old Historian) so it made sense to continue building on these assets.

“ArchestrA is a good integration platform and AVEVA System Platform enables future integration of other [IS³] solutions like MES,” says CSI System Engineer Rikus Wouda. “Also, ArchestrA and InBatch are proven technologies with a huge support base and InBatch (now AVEVA Batch Management), as well as simplifying the configuration of complex batch processes, integrates well with System Platform.”

InControl (a PC-based software version of a PLC), however, had been discontinued and one of the first tasks was to reverse-engineer its functionality in order to transfer the well-designed S88 standards to the new PLC.

The rest of the software was upgraded to their latest versions where AVEVA Batch Management was used for operations management and InTouch continued its role as HMI and supervisory controller. The ArchestrA-based System Platform was introduced as the integration layer while Historian and Information Server were used for information management.

“For the sake of better efficiency and control and the fact that operators can switch between manual control and [AVEVA Batch Management], we wanted to communicate with the PLC through one ArchestrA object,” says CSI Senior Systems Engineer Nkhensani Mbanyele. “So we configured a single master ArchestrA object that receives the [AVEVA Batch Management] model as well as inputs from InTouch and which then communicates these to the PLC.”

Conclusion

With this virtualisation project, L’Oréal was able to mitigate the risk associated with overloaded and obsolete hardware and by upgrading their MES/MOM and HMI capabilities to the latest technologies the company reduced the business risk associated with legacy systems that had exceeded their life cycles.

The result was better-informed personnel, improved system design and reliability as well as reduced hardware support effort and cost through virtualisation of the manufacturing servers.

Benefits

- AVEVA Batch Management simplifies recipe management and batch tracking

- The end-user can maintain the recipe database without outside help

- Built-in version control

- More consistent quality and batch duration

- Improved availability, reliability and sustainability of the process environment thanks to hardware independence

- System integrators can replicate the production environment easily for development and testing purposes

- Streamlined disaster recovery process means that there is now minimal downtime