AVEVA aiming to drive sustainability by helping industries digitally transform

As an AVEVA Select partner we are proud to be the sole AVEVA distributor for the sub-Saharan region and drive the approach AVEVA is taking when it comes to sustainability.

At AVEVA, sustainability has never been higher on the agenda! Our partner is taking actions to embed sustainability into our operations and our core business strategy. They are committed to leading sustainable innovation and to work in partnership with others to make a more just, net-zero world a reality for the next generation.

They will manage sustainability through the lens of their technology handprint, operational footprint, and inclusive culture. This approach was delivered to our region in Southern Africa at our Annual X-Change User Conference that took place in May 2022.

Our media partner, Engineering News, covered this topic in further detail in an article below:

AVEVA aiming to drive sustainability by helping industries digitally transform

As an AVEVA Select partner we are proud to be the sole AVEVA distributor for the sub-Saharan region and drive the approach AVEVA is taking when it comes to sustainability.

At AVEVA, sustainability has never been higher on the agenda! Our partner is taking actions to embed sustainability into our operations and our core business strategy. They are committed to leading sustainable innovation and to work in partnership with others to make a more just, net-zero world a reality for the next generation.

They will manage sustainability through the lens of their technology handprint, operational footprint, and inclusive culture. This approach was delivered to our region in Southern Africa at our Annual X-Change User Conference that took place in May 2022.

Our media partner, Engineering News, covered this topic in further detail in an article below:

“This agreement enables clients to kindle a cultural shift towards anti-fragility and resilience. It accelerates their digital transformation journeys while ensuring alignment to global and regional marketing trends as well as technology. Being chosen for the Select Partnership program is not only a testament to the value that IS³ brings to AVEVA but also signifies the incredible progress that has been made in the reshaping of the industrial automation market”

Dion Govender – CEO, Digital Industries (Pty) Ltd

“An AVEVA Select partner can leverage the full breadth of our portfolio to empower customers as they double down on their digital strategies. Designed for our distributors, the unique AVEVA Select program helps them to optimize on opportunities and support customers to succeed in their digital transition. “We are pleased to welcome IS³ to the AVEVA Select family and look forward to developing and capitalizing on mutually beneficial growth strategies.”

Kerry Grimes – Head of Global Partners, AVEVA.

About IS³

About IS³

Driven by their ability to see the limitless potential of technology to empower people and transform businesses, IS³ provides industry software solutioning and support that enables individuals, teams, and businesses to move efficiently, seamlessly, and compliantly through their digital transformation journey. Their superior industrial software solutions include production, operations, production performance, manufacturing, intelligence, and business process management.

About AVEVA

About AVEVA

AVEVA is a global leader in industrial software, driving digital transformation and sustainability. By connecting the power of information and artificial intelligence with human insight, AVEVA enables teams to use their data to unlock new value. We call this Performance Intelligence. AVEVA’s comprehensive portfolio enables more than 20,000 industrial enterprises to engineer smarter, operate better and drive sustainable efficiency. AVEVA supports customers through a trusted ecosystem that includes 5,500 partners and 5,700 certified developers around the world. The company is headquartered in Cambridge, UK, with over 6,500 employees and 90 offices in over 40 countries.

About AVEVA Select

About AVEVA Select

The AVEVA Select program is designed for partners with full access to AVEVA’s comprehensive software portfolio, enabling them to help companies accelerate their digital transformation journey. AVEVA Select aligns to both market and technology trends, with programs designed to suit every product and solution specialization in the engineering and industrial segments. By leveraging the breadth of the AVEVA software portfolio, AVEVA Select partners can now help customers simplify design, optimize production, and maximize performance.

About IS³

About AVEVA

About AVEVA Select

About IS³

Driven by their ability to see the limitless potential of technology to empower people and transform businesses, IS³ provides industry software solutioning and support that enables individuals, teams, and businesses to move efficiently, seamlessly, and compliantly through their digital transformation journey. Their superior industrial software solutions include production, operations, production performance, manufacturing, intelligence, and business process management.

About AVEVA

AVEVA is a global leader in industrial software, driving digital transformation and sustainability. By connecting the power of information and artificial intelligence with human insight, AVEVA enables teams to use their data to unlock new value. We call this Performance Intelligence. AVEVA’s comprehensive portfolio enables more than 20,000 industrial enterprises to engineer smarter, operate better and drive sustainable efficiency. AVEVA supports customers through a trusted ecosystem that includes 5,500 partners and 5,700 certified developers around the world. The company is headquartered in Cambridge, UK, with over 6,500 employees and 90 offices in over 40 countries.

About AVEVA Select

The AVEVA Select program is designed for partners with full access to AVEVA’s comprehensive software portfolio, enabling them to help companies accelerate their digital transformation journey. AVEVA Select aligns to both market and technology trends, with programs designed to suit every product and solution specialization in the engineering and industrial segments. By leveraging the breadth of the AVEVA software portfolio, AVEVA Select partners can now help customers simplify design, optimize production, and maximize performance.

IS³’s Customer Success Stories

Speak to an Expert

Contact one of our highly qualified sales representatives to see how we can assist with maximising your potential!

AEL (now AECI Mining Explosives) gives its customers a bigger bang for their buck with help from IS³

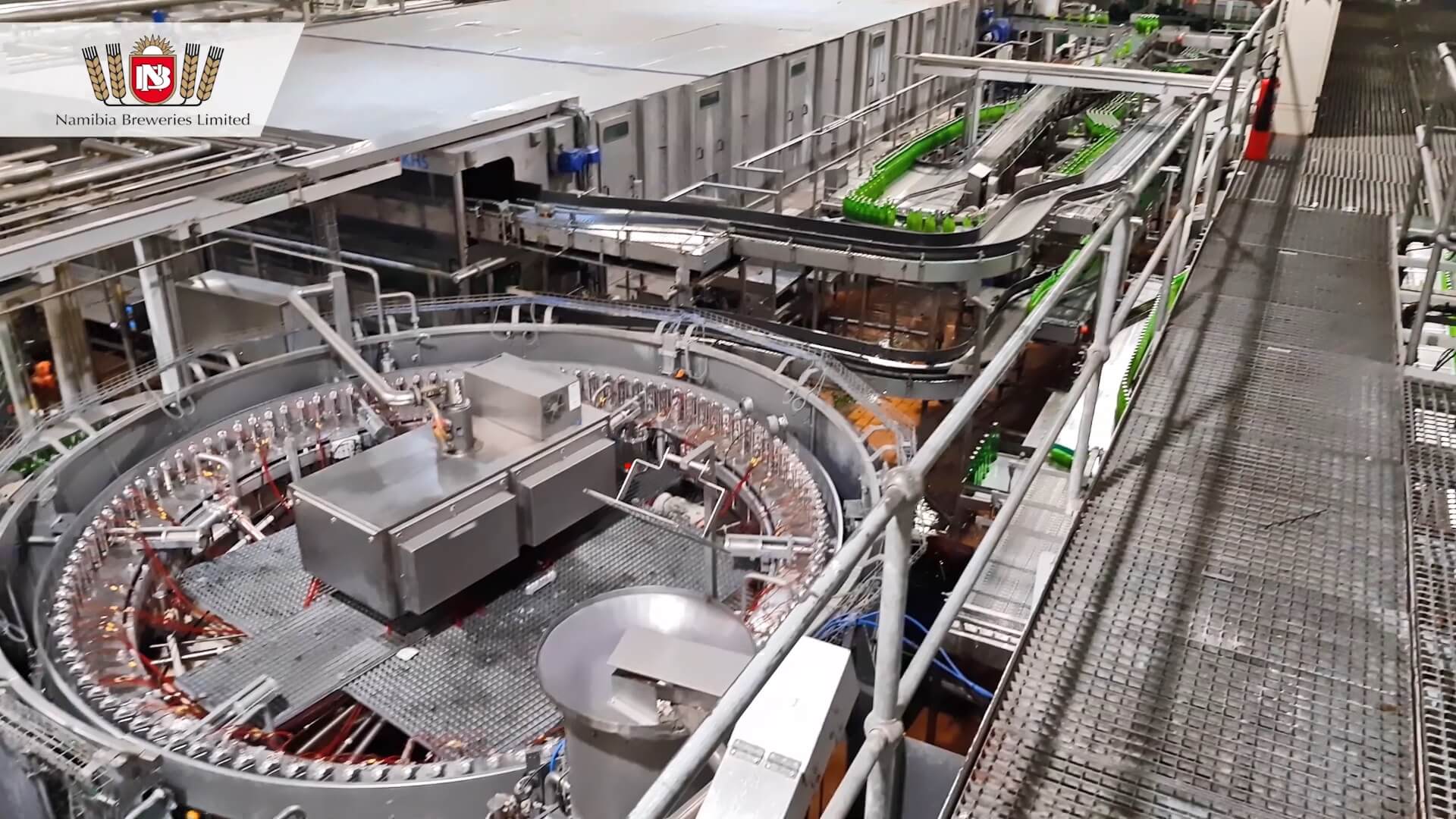

There are few industries that demand more focused attention than the manufacture of explosives. Reliability, accuracy, safety and predictability are top of the agenda for the manufacture of detonators, since they start the explosion process and are responsible for its timing and precision. AECI Mining Explosives saw the need for a raw material and product tracking solution that would eliminate process variability while providing traceability into the composition of product batches.

The new raw material and product tracking system gives us a far greater degree of control over sustained quality, product consistency and process improvement.”

Ronald Huggins, Company Control Systems Engineer – AECI Mining Explosives

Background

At the Initiating Systems Automated Plant (ISAP), AECI Mining Explosives manufactures detonator assemblies consisting of raw materials, delay powders, delay elements, tubes and shock tubes. Previously, the batch tracking of raw materials and products used in the manufacture of detonators was done with a paper-based system which was prone to human error. It was time for a change and with the business objectives of improving customer relations and AECI Mining Explosives’s competitiveness, as well as consolidating the use of raw materials, the company decided that a greater degree of automation was desirable. Any chosen solution would also have to meet the operational requirements of improving product quality (stop faulty products in their tracks), tracking back from the customer into the batch process to determine the cause of any product failure, decrease human error and assist in the evaluation of the properties and performance of raw materials used in production.

Solution Selection

AECI Mining Explosives chose system integrator Advansys for the implementation because of previous experience and their wide knowledge of the AVEVA (formerly Wonderware) product range. AECI Mining Explosives had previously selected Wonderware’s Production Events Module (today part of the Equipment Operations Module of AVEVA System Platform) to capture real-time process data, link the batch process to execution and to provide detailed batch data reports for analysis. The Production Events Module would track what material was consumed and produced by the process and would work in conjunction with Historian, AVEVA System Platform (Galaxy Repository, Industrial Application Server) and dual-redundant Application Object Servers.

Implementation

“In my opinion, the ability to develop templates which suit most of the tracking functions needed as well as their reusability are two of the most outstanding features of the underlying ArchestrA technology,” says Braam Venter, Megatronics Engineer, Advansys (Pty) Ltd. “Another highlight was the ease of use and the ability to integrate with the Historian .NET components.”

Advansys used a top-down approach which included addressing the operator interfaces which consisted of existing WinCC Flexible touch panels that could only communicate with the PLC. This meant that all the operator instructions had to be routed through the PLC, which led to the development of standard screens with text fields to view messages from the Industrial Application Server. The ability to manage text messages and HMI data from within the Industrial Application Server reduced implementation and commissioning times.

Real-time process data is captured at each production event and this can then be used to analyse if a certain batch is faulty. A production database was implemented for raw material inputs for the production personnel as well as formula management for the various Delay Powder recipes. This database is used as a scanner interface between the Industrial Application Server and the scanners at various production screens.

“The Industrial Application Server is used to drive the production processes via a PLC and WinCC Flexible touch panels,” explains Venter. “The relevant data is then logged in a ProdDB (PEM database). Formulae and raw material data are stored in a production database. A production website has been developed for raw material and formula inputs as well as tracking information. An SAP interface table had to be designed for communicating product quantity produced and consumed.”

A database connection .net object was developed by Advansys to ease the integration with the production database. A scanner driver was written to read UDP packets from the scanner RS232 to UDP converters. This scanner driver then updates the production database with the scanned data.

Benefits

- AECI Mining Explosives now has an accurate tracking system on which the company and its customers can rely

- Improved competitive positioning

- No more paperwork means less human error and improved operator confidence

In my opinion, the ability to develop templates which suit most of the tracking functions needed as well as their reusability are two of the most outstanding features of the underlying ArchestrA technology.”

Braam Venter, Megatronics Engineer, Advansys (Pty) Ltd

Conclusion

The new raw material and product tracking system at AECI Mining Explosives’s Initiating Systems Automated Plant is helping the company maintain its century-old formula of agility in dealing with market and technological developments. Accurate and rapid backtracking is helping to pinpoint and isolate problem areas faster than ever before and to continuously improve on product quality while minimising waste and evaluating raw material specifications. As such, the new tracking system is helping to keep the wheels of the mining industry moving more effectively at a time when it needs it most.