AVEVA Activity Visualisation Platform

AVEVA Activity Visualisation Platform

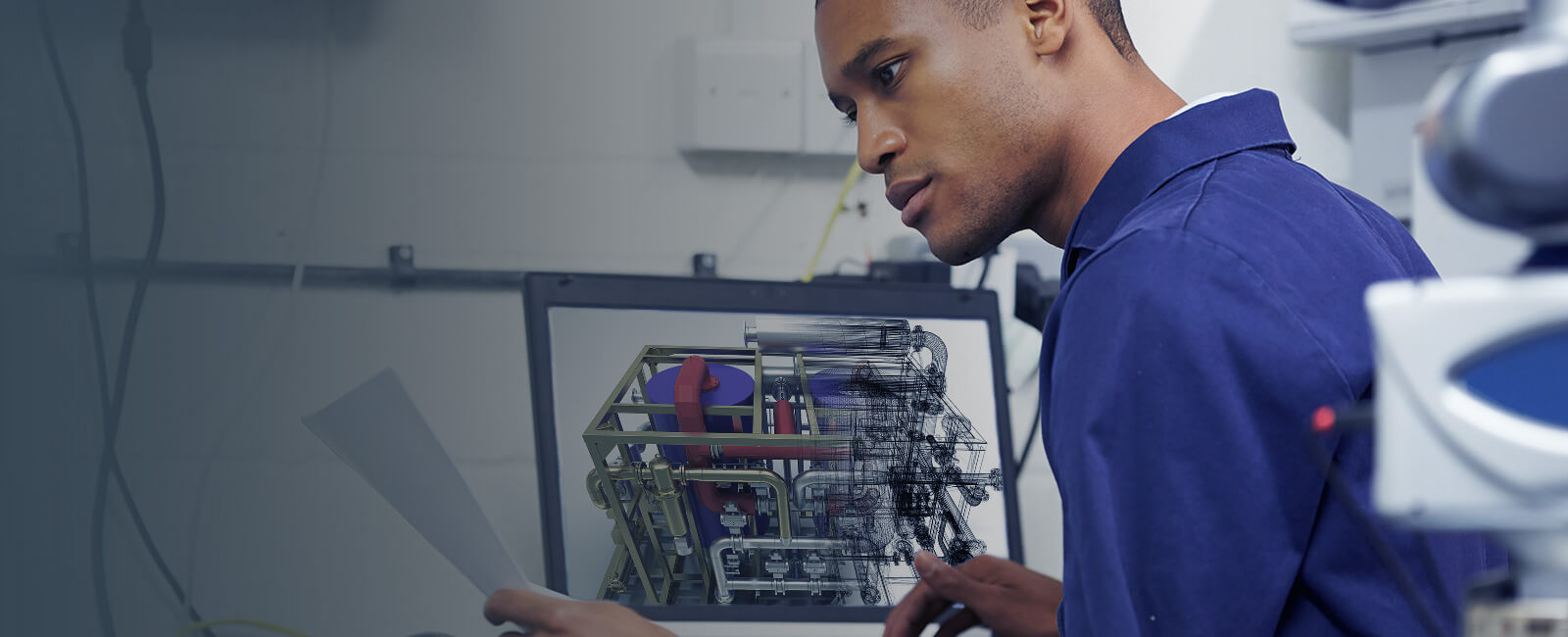

It’s a well-known fact that people learn best by doing. However, when making a mistake can lead to catastrophic consequences, opportunities for learning ‘on the job’ can be severely curtailed. The aviation industry overcame this obstacle by developing sophisticated flight simulators which have resulted in major improvements in flight safety as well as preparatory training for almost any scenario. Now, AVEVA’s Activity Visualisation Platform (AVEVA AVP™) offers a similar capability for the plant, offshore and marine industries.