Advansys has a good knowledge of the Food and Beverage industry in general and the brewing industry in particular. “[Their] specific advantage is knowledge of not only the beer making process but also the manufacturing system architecture that we use such as our eQMS, which is our quality/MES system,” says du Toit.

In addition, if any custom development had to be done, the expert use of the ArchestrA Application Object Toolkit was important. This gives the ability for any custom development to conform with SAB’s architecture and standards while making it easy for the engineers at regional level to understand and maintain the system.

“Lastly, AVEVA Intelligence is a Business Intelligence tool and Advansys’s knowledge of data warehousing was important to understand and implement the project on a tight timeline,” concludes du Toit.

Implementation

“Starting at the regional level, we wanted to make use of the existing infrastructure at the regions and did not want to introduce anything that would affect the performance of the historians, application object servers or even the PLCs,” says du Toit.

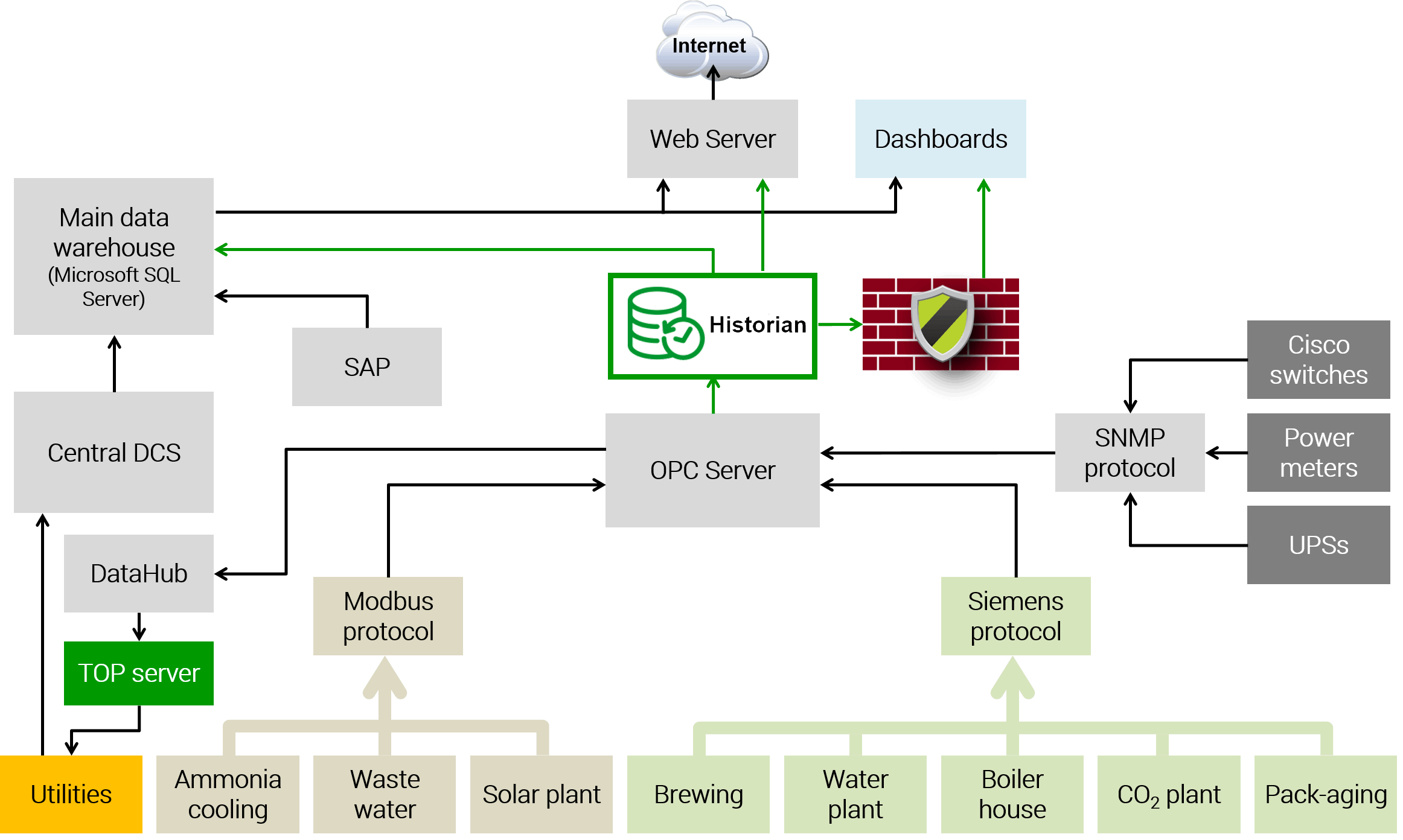

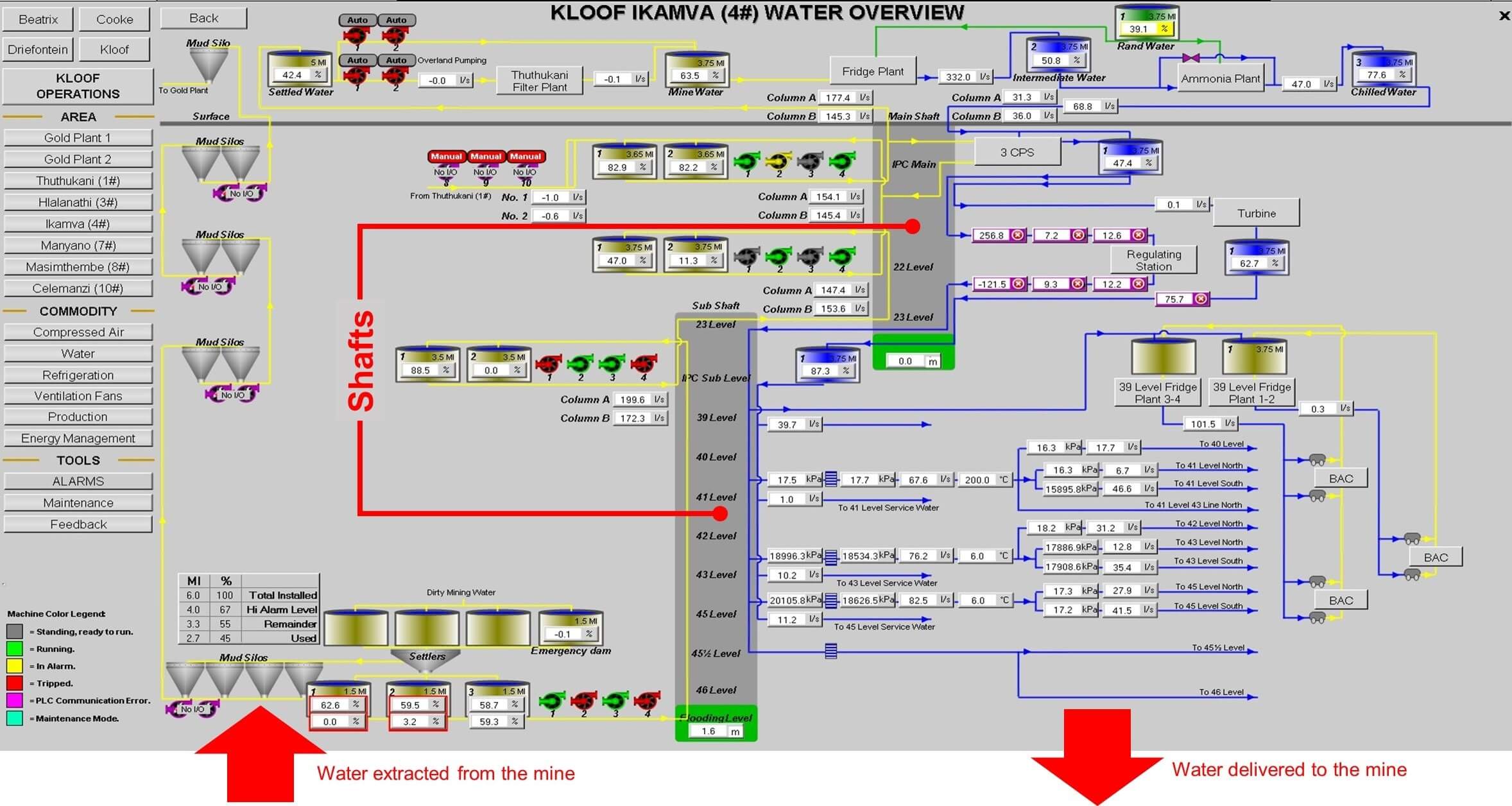

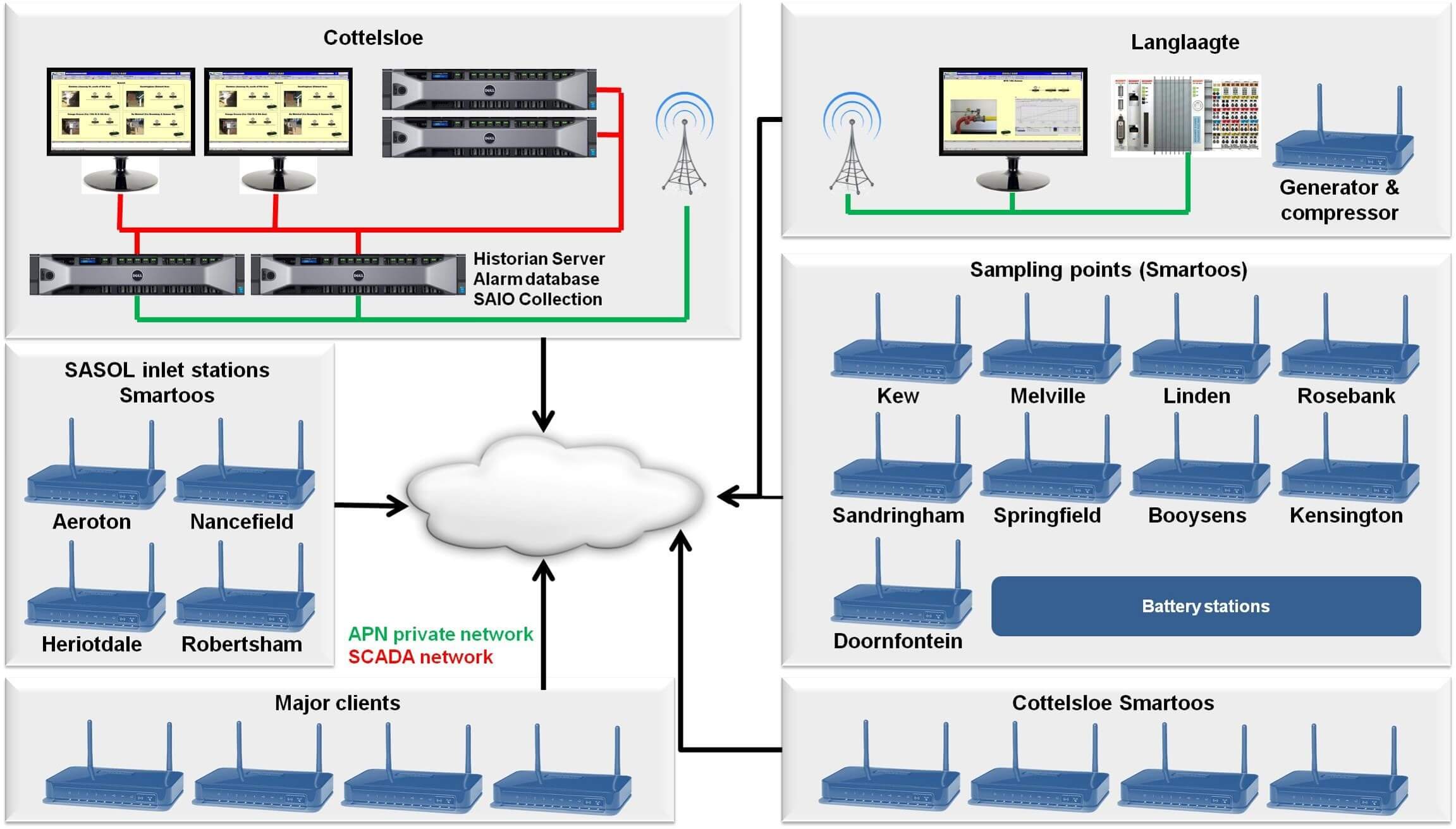

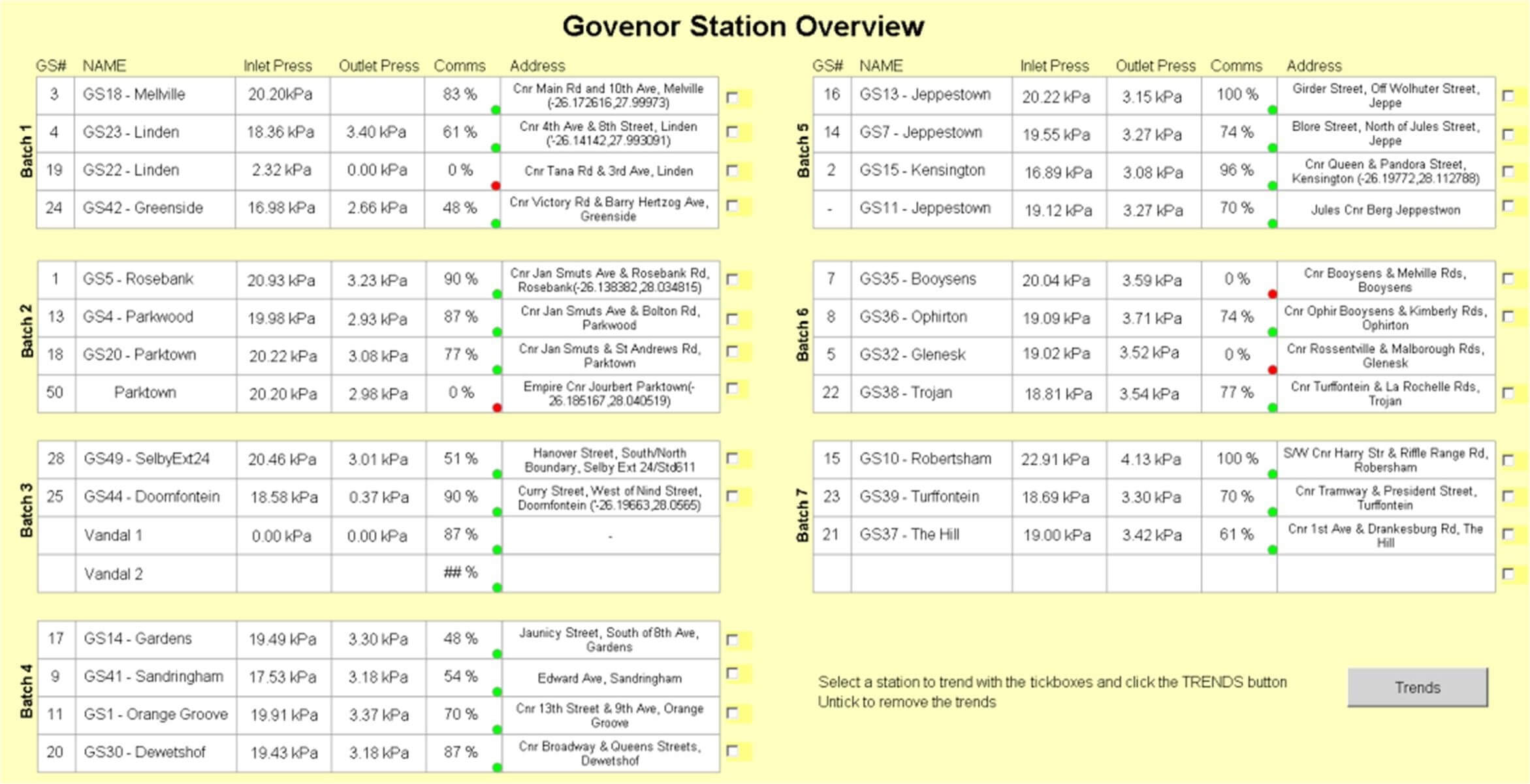

The project team drew up the required regional system architecture shown in figure 1 which collates KPIs from the PLCs as well as the Historians and MES servers for storage in the regional data warehouse from which it can be extracted and viewed in dashboard form according to the needs of users.

This regional architecture was replicated seven times for each of the regions and connected to the central data warehouse at head office, where the dashboard views not only represent an aggregated picture but also allow drilling down to the views of each region independently.

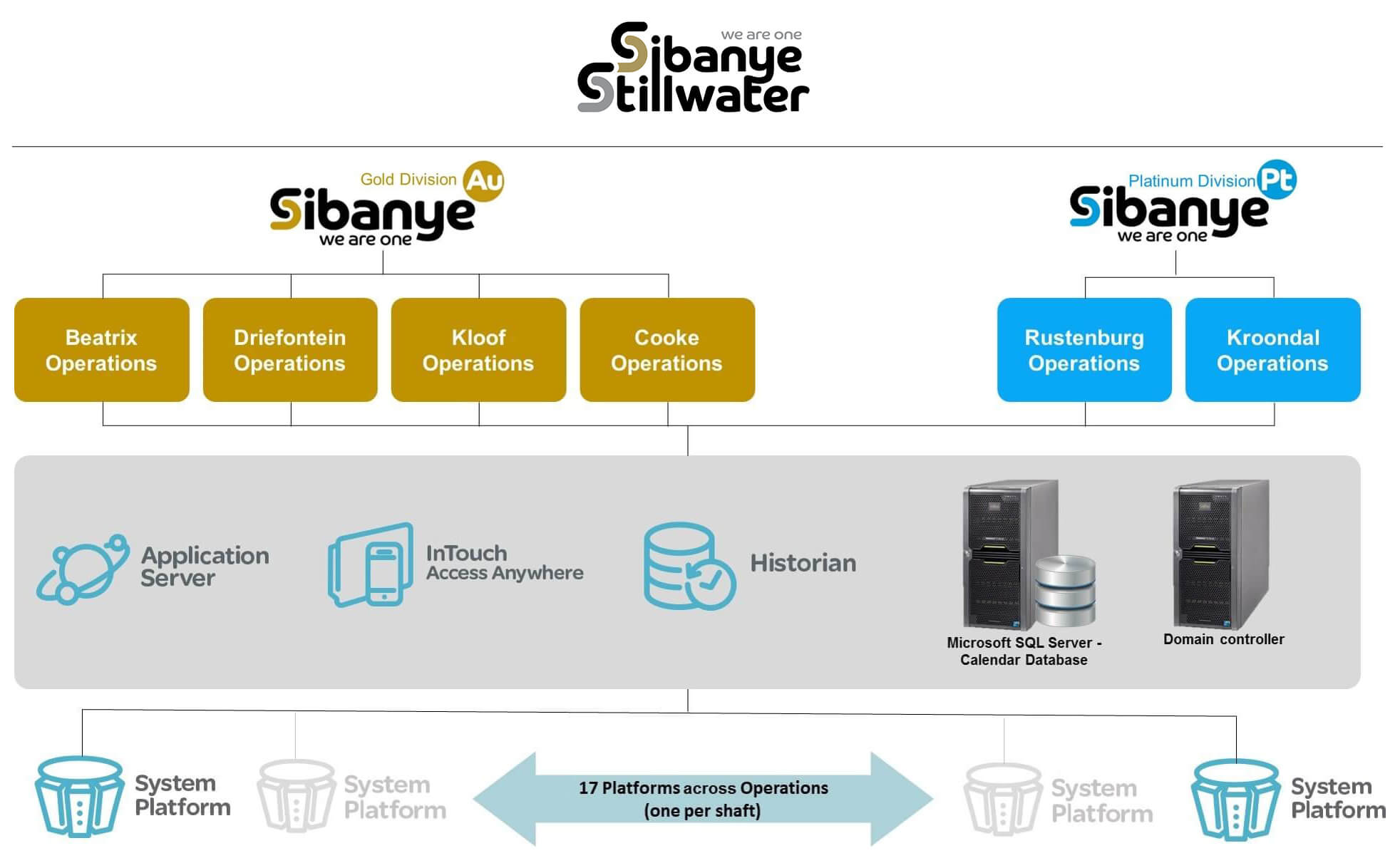

“SAB stipulated that we make use of the existing ArchestrA System Platform install-base, providing centralised change management, change propagation and it’s user-friendly Integrated Development Environment (IDE) for all data retrieval configuration,” says Advansys Director Graeme Welton.

The main reasons for this were that SAB didn’t want another system to maintain and ArchestrA is already the standard system control platform at all the breweries. Systems engineers are familiar with its IDE and the System Platform provides built-in change propagation and object derivation, a deployment installation model as well as an integral security model. In other words, everything was in place to allow Advansys to focus on the Intelligence application and not spend engineering time on fundamentals.

This phase of project Dash focused on collecting and collating diagnostic data with respect to system performance, traffic volumes, CPU usage, scan times, memory usage, message status (MSMQ), I/O Server item counts (total, active, etc.), disc space availability, unprocessed SQL messages and many more. This would include everything from the PLC, Server Platform, the process and the ArchestrA engine to the I/O Server, the file system, Microsoft Message Queue and any SQL database (MES).

“Because of the nature of this data, most of which comes from operating system diagnostics, as well as SAB’s requirement to use ArchestrA, we decided to use the ArchestrA Object Toolkit which gave us full use of the ArchestrA Object Framework and access to low-level C#.Net coding,” says Welton. “This approach also allowed us to use standard, out-of-the-box alarm and history primitives and compile editors for easy configuration. This all meant that no scripting was required for engineers to configure the data retrieval objects.”

Welton believes that the dashboard development tool is much more than it appears at first and that IS³ has produced a solution whereby almost anyone with some basic training can collect and collate information from virtually any combination of sources to suit their needs. “This is rather different from traditional Business Intelligence tools that require large IT teams to support and develop.”

Benefits

“I feel I should comment on three important aspects of the project,” says du Toit. “First of all, time; after the testing and development phase, we were able to roll out the project to the rest of the sites and commission within 2 months!

This is a reflection on the power of the underlying ArchestrA technology. Then there’s the matter of cost. The time saved with the project roll-out had a direct impact on the cost and we were able to finish within budget. The third point is the exceptional quality of the work delivered by Advansys.”

- One immediate benefit was risk reduction. With an immediate view of the status of each system, engineers were able to detect issues that impact performance of the various systems under scrutiny.

- Cross-platform comparison and analysis make decision making easy when deciding on deployment of areas.

- Cross-regional analysis shows trends and areas to focus on for development or where support should be given.