Windhoek, Namibia

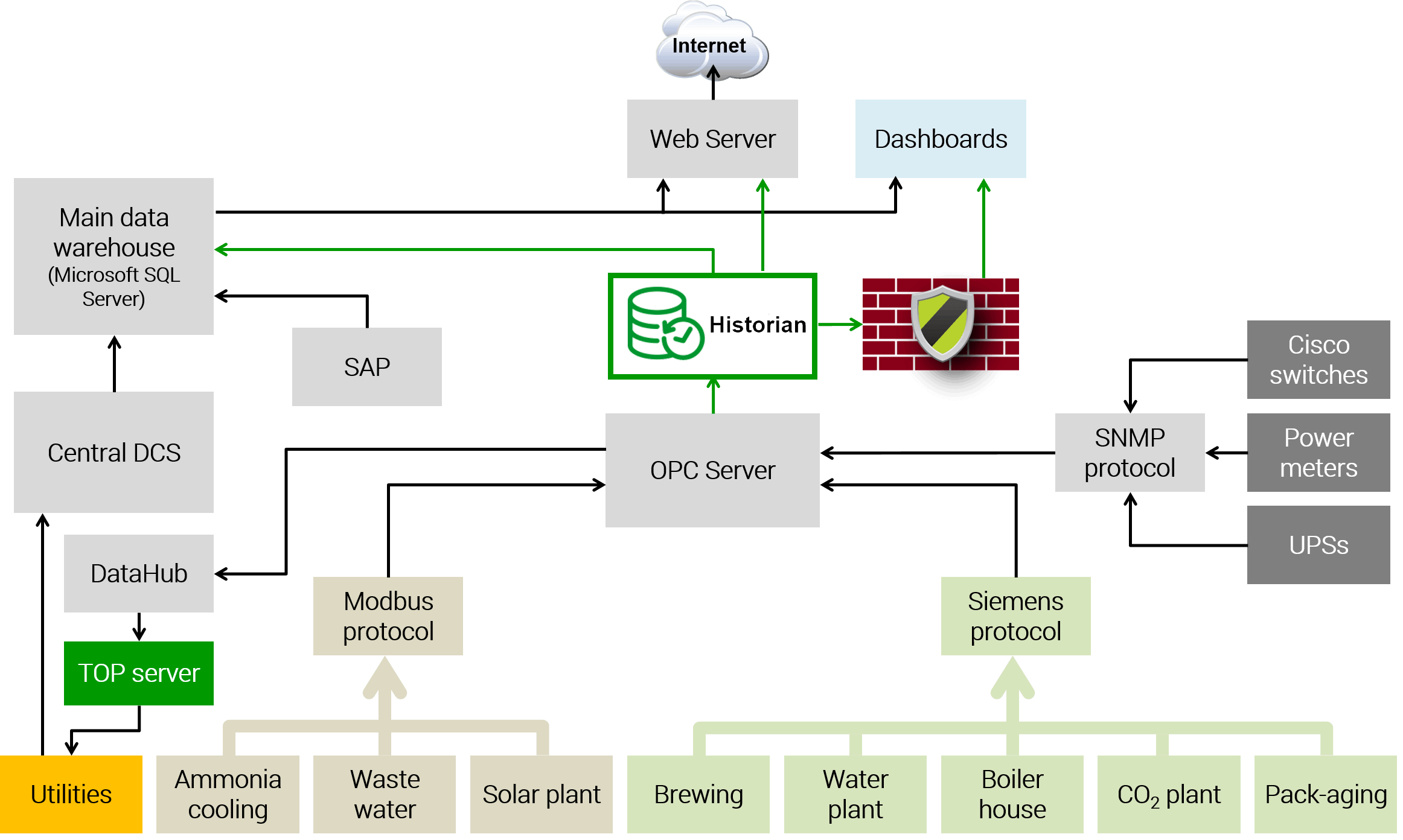

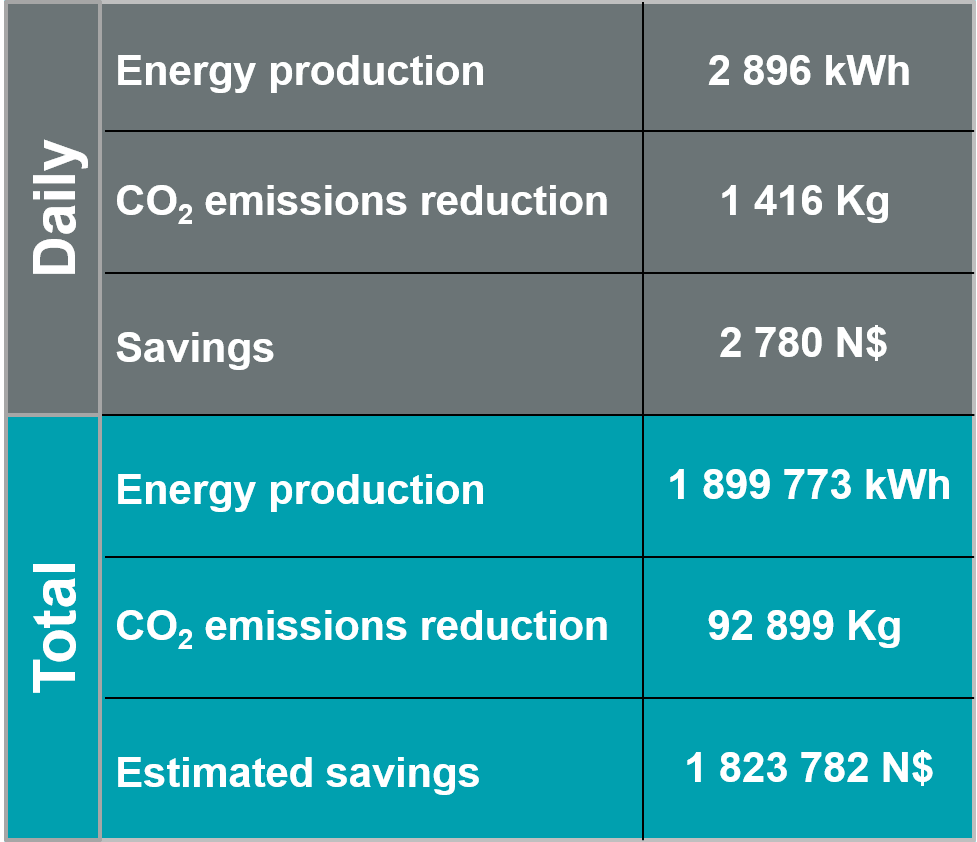

Optimal utilities management contributes to a greener environment and a healthier bottom line at Namibia Breweries Limited (NBL) where AVEVA Historian from IS³ helps to generate daily, weekly and monthly consumption reports for water, electricity, chemicals, thermal energy, solar generation, carbon dioxide and air and to compare results with KPI targets.

Linking Historian tags to the company’s production system has also led to faster and more accurate problem detection.

Background

With regard to renewable energy, NBL has put into practice what others only talk about. The company has a 1MW roof-mounted solar plant with more than 4000 panels, 66 inverters and 4 cluster controllers. The whole system is connected to three of the company’s generator sections. When it was installed in 2013, it was the largest hybrid system in the world and it also made NBL completely self-sufficient regarding electrical power.

But this was only the start. Electricity, though a major component, is only one factor in the complex world of utilities which, today, are highly significant contributors to product costs, competitiveness and profitability. And there’s more to effective utilities management than simply watching the meter.

A Manufacturing Operations Management Survey conducted by LNS Research showed that the top two operational challenges for meeting Strategic Manufacturing Objectives were that companies had to deal with disparate systems and the lack of cooperation across their different departments.

“In our case, we have the brewing, packaging and distribution departments,” says André Engelbrecht, Manager: Industrial Control Systems, NBL “Each of them focuses on doing their job to the best of their ability but without necessarily much concern for the common denominator that makes it all possible; utilities.”

And so NBL decided to unify their various departments into a cohesive entity that could make real-time business decisions with regard to utility usage based on a single version of the facts.

The scope of the implementation would include access to the CO2 plant, NH3 Ammonia cooling, boiler house, water treatment plant, sterile air plant and power meters.